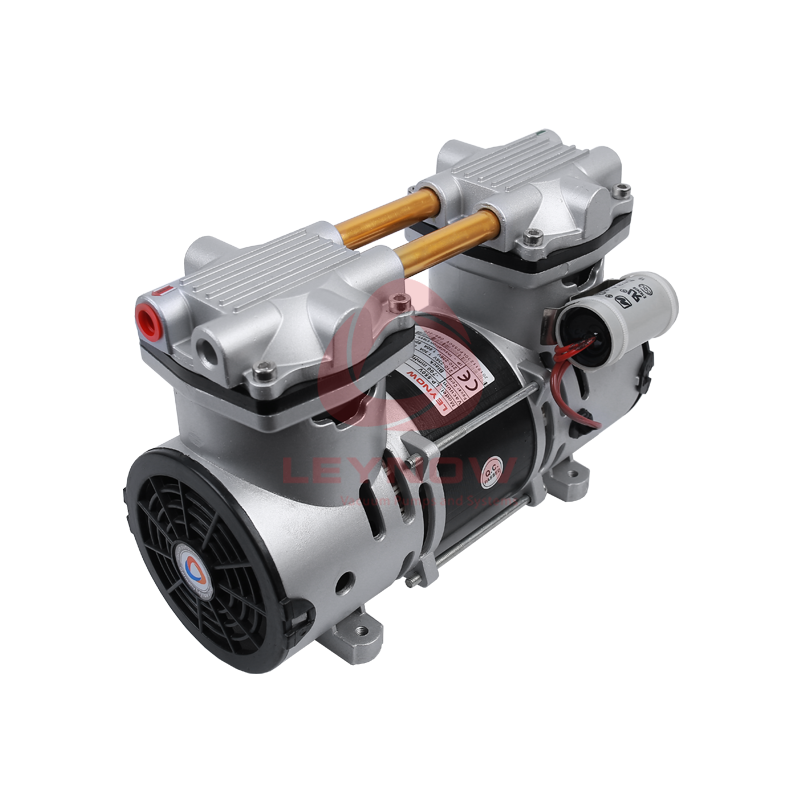

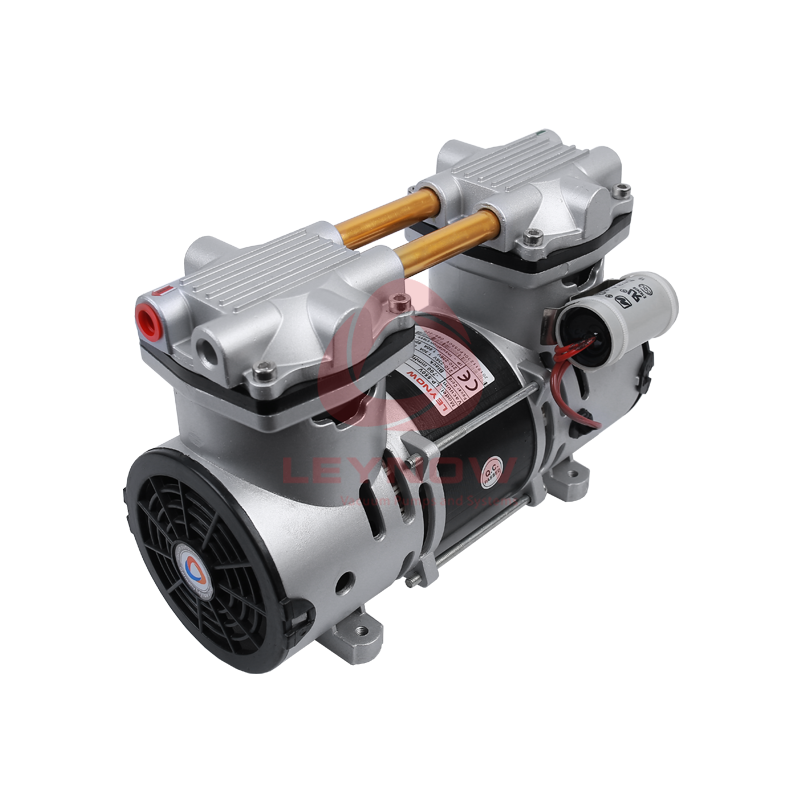

The piston vacuum pump is a reciprocating vacuum pump that pumps air by periodically changing the working volume of the pump chamber through the reciprocating motion of the piston. Piston vacuum pumps are widely used to remove gases in vacuum impregnation, vacuum treatment of molten steel, vacuum distillation, vacuum crystallization, vacuum filtration, etc. Let's take a detailed look at the working principle, structure, application industries, usage precautions and maintenance issues of piston vacuum pumps.

1. Introduction to the working principle of piston vacuum pump

The main components of the piston vacuum pump are the cylinder and the piston that makes reciprocating linear motion in it. The driving of the piston is completed by the crank connecting rod mechanism. In addition, there are two components: the exhaust valve and the suction valve. When the pump is running, driven by the electric motor, the piston in the cylinder is reciprocated through the action of the crank connecting rod mechanism. During the reciprocating motion, as the volume of the left cavity of the cylinder continues to increase, the density of the gas in the cylinder decreases, forming a pumping process. At this time, the gas in the container passes through the suction valve. When the piston reaches the rightmost position, the gas in the cylinder Completely filled with gas. Then the piston moves from the right end to the left end. At this time, the suction valve is closed. The gas in the cylinder is gradually compressed as the piston moves from right to left. When the pressure of the gas in the cylinder reaches or slightly exceeds one atmosphere, the exhaust valve is closed. Open it and exhaust the gas into the atmosphere to complete a working cycle. This cycle is repeated until the gas pressure in the pumped volume reaches the required level.

2. Structure of piston vacuum pump

The main components of piston vacuum pump include cylinder, piston, air valve, suction valve, exhaust valve, etc. Among them, the cylinder is the main part of the piston vacuum pump. As the volume of the left chamber of the cylinder continues to increase, the density of the gas in the cylinder decreases, resulting in a pumping process. The piston is a component that makes reciprocating linear motion in the cylinder. Through the action of the crank connecting rod mechanism, the piston in the cylinder is made to reciprocate. The suction valve and exhaust valve respectively control the inlet and outlet of gas to achieve the purpose of air extraction.

3. Application industries of piston vacuum pumps

Piston vacuum pumps are widely used in manufacturing, laboratories, medical, aerospace and other fields. Specific application industries include:

● 1. Laboratory: Vacuum pumps can be used to prepare high-purity substances or create a vacuum environment in the laboratory.

● 2. Manufacturing industry: Vacuum pumps can be used to manufacture semiconductors, optical components and other products that require a high-purity environment.

● 3. Medical: Vacuum pumps can be used to manufacture medical equipment, such as magnetic resonance imaging machines.

● 4. Space science: Vacuum pumps can be used to manufacture spacecraft, such as satellites, rockets, etc.

4. Precautions for use and maintenance of piston vacuum pumps

● 1. Before use, you need to check the sealing performance of the pump to ensure that the pump is well sealed.

● 2. When using, it is necessary to select the appropriate pump type and vacuum degree according to the specific situation.

● 3. Pay attention to safety when using the vacuum pump to avoid dangers such as explosion or fire in the pump.

● 4. The vacuum pump requires regular maintenance and cleaning to ensure its normal operation.

● 5. When using a vacuum pump, you need to pay attention to the temperature of the pump and the use of lubricating oil to avoid affecting the normal operation of the pump.

● 6. When not in use for a long time, the oil in the pump needs to be drained to prevent oil deterioration from affecting the service life of the pump.

In short, the piston vacuum pump is a vacuum pump with stable performance and easy use, and has a wide range of applications. It is necessary to pay attention to safety during use and perform regular maintenance and upkeep to ensure its normal operation.

Article source:https://www.leynow.com.cn/news/822.html

Disclaimer: If the article needs to be reprinted, please indicate the source. Some articles and pictures on this site come from online editors. If there are any copyright issues, please communicate and resolve them in time.

LeyNow Company is a high-tech enterprise that develops, sells vacuum pumps and provides solutions in the vacuum field. It provides users with the most reliable, safe and easy-to-use vacuum equipment products and high-quality professional services to help global customers and partners achieve success. The company's main products include: rotary vane vacuum pumps, screw vacuum pumps, Roots vacuum pumps, piston vacuum pumps, etc.

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business CHN

CHN