Screw vacuum pump technological innovation: efficient purging method leads a new trend in industrial vacuum

In the rapidly developing industrial field, screw vacuum pumps have become indispensable key equipment in many industries due to their efficient and stable performance. With the continuous advancement of technology, the purging methods of screw vacuum pumps have also been optimized and upgraded. Among them, cooling purging, inflatable sealing and aeration technology have become important innovations leading the new trend in the industry.

1. Cooling and purging technology: efficient cooling to ensure stable operation

Cooling purge technology is a vital function in screw vacuum pumps. It is mainly used to cool the rotor and pump body to ensure that the pump can maintain stable working conditions under long-term, high-load operation. During the operation of the pump, the exhaust gas will generate a large amount of compression heat after being compressed by the rotation of the rotor. This heat can reach 100 to 200°C at the discharge end, which has a serious impact on the performance and life of the pump.

In order to effectively reduce this heat, engineers developed cooling purge technology. This technology introduces dry, clean air as the cooling medium to purge and cool the pump chamber. An air filter is installed at the air inlet end to ensure the quality of the air entering the pump chamber and prevent impurities from causing damage to the pump. The application of cooling purge technology not only effectively reduces the temperature of the pump body, but also improves the working efficiency and stability of the pump.

However, the application of cooling purge technology also brings certain problems. Since the purge gas will occupy the pumping speed of the pump, the actual effective pumping speed of the vacuum pump will decrease. The greater the purge volume, the more obvious the impact on the pump pumping speed. Therefore, in practical applications, the purge amount needs to be reasonably adjusted according to specific working conditions to achieve optimal performance and economic benefits.

2. Inflatable sealing and aeration technology: isolate lubrication and pump chamber to ensure safe operation

During the operation of the screw vacuum pump, the labyrinth seal is an important measure to prevent gas leakage between the lubricating oil chamber and the pump chamber. However, in some special working conditions, the labyrinth seal may not be able to meet the needs of process production. At this time, inflatable means can be used to enhance the sealing effect of the labyrinth seal to completely isolate the lubricating oil chamber and the pump chamber.

Inflatable sealing technology usually uses air, nitrogen or inert gas as the sealing medium. These media enter the pump chamber through the charging port and form a gas barrier to effectively prevent gas leakage between the lubricating oil chamber and the pump chamber. The pressure of the sealing medium is generally 0.5~1.0Kg/cm2G, which can be adjusted according to actual working conditions.

In addition to inflatable sealing, air entrainment technology is also an important technology in screw vacuum pumps. Aeration mainly reduces the concentration of condensable gases and corrosive gases in the pump by introducing external gas, thereby reducing the damage of these gases to the pump. The air inlet is located on the side of the pump body to facilitate users to access external air sources.

In industrial production, screw vacuum pumps are usually connected with other equipment on the production line to form a complete production system. In this system, the performance and stability of the screw vacuum pump have an important impact on the operating efficiency and product quality of the entire production line. Therefore, the application of inflatable sealing and air entrainment technology not only improves the performance and stability of the screw vacuum pump, but also provides a strong guarantee for the operation of the entire production system.

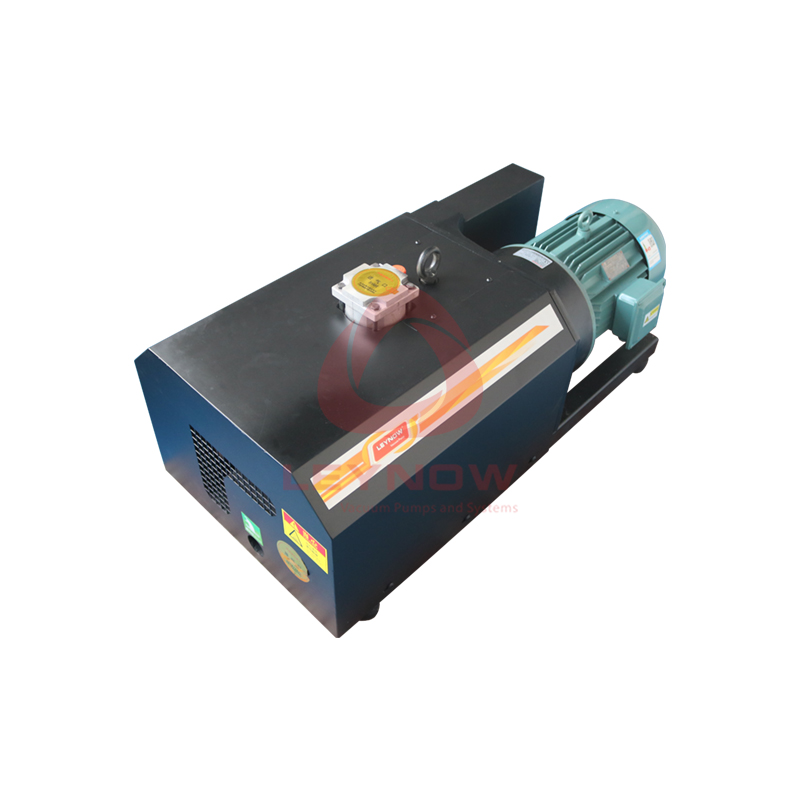

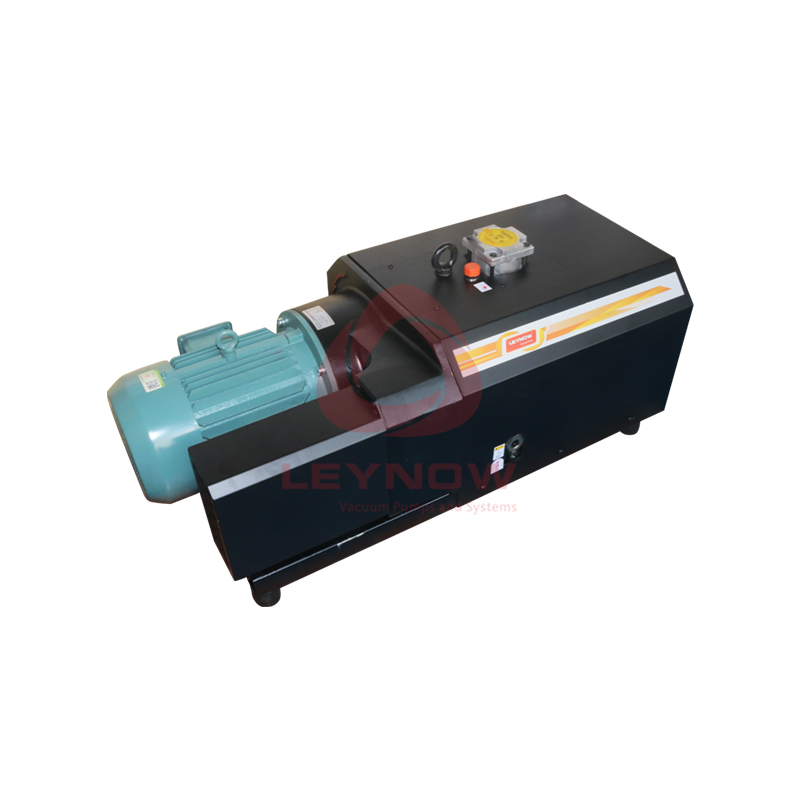

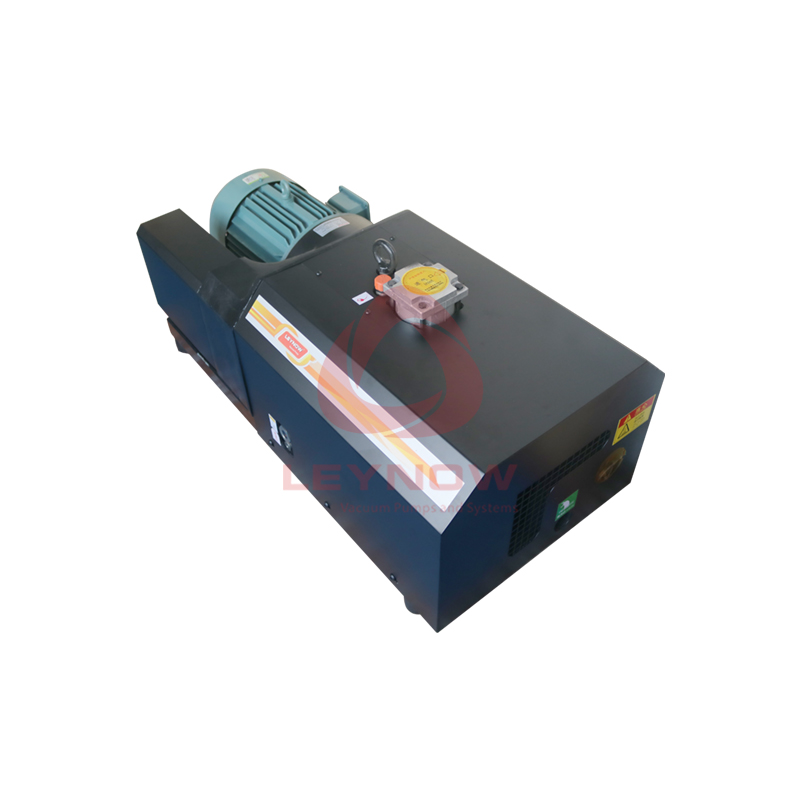

3. Application of LeyNow vacuum pump in screw vacuum pump purging technology

As a leading company in the industry, LeyNow Vacuum Pump has achieved remarkable results in screw vacuum pump purging technology. LeyNow vacuum pumps have been widely used in the field of screw vacuum pumps due to their excellent quality and stable performance. In terms of cooling and purging, the dry and clean air provided by Leno vacuum pump is used as the cooling medium, which effectively reduces the temperature of the pump body and improves the working efficiency and stability of the pump. At the same time, Leno Air Pump also provides various types of inflatable sealing and aeration equipment to meet the needs of different users.

In practical applications, LeyNow vacuum pumps work closely with screw vacuum pumps to form a complete purging system. The system can automatically adjust the purge volume and sealing medium pressure according to specific working conditions to achieve optimal performance and economic benefits. In addition, LeyNow vacuum pumps also provide professional technical support and after-sales service to ensure that users can receive timely and effective help during use.

4. Conclusion

As a key equipment in the industrial field, the performance and stability of screw vacuum pumps have an important impact on the operating efficiency and product quality of the entire production line. With the continuous advancement and innovation of technology, the purging technology of screw vacuum pumps has also been optimized and upgraded. The application of cooling purge technology, inflatable sealing and aeration technology not only improves the performance and stability of the screw vacuum pump but also provides users with a more convenient and efficient use experience. As an innovative enterprise in the industry, Leno Vacuum Pump has achieved remarkable results in screw vacuum pump purging technology and made positive contributions to the development of the industry.

Article source:https://www.leynow.com.cn/news/1047.html

Disclaimer: If the article needs to be reprinted, please indicate the source. Some articles and pictures on this site come from online editors. If there are any copyright issues, please communicate and resolve them in time.

LeyNow Company is a high-tech enterprise that develops, sells vacuum pumps and provides solutions in the vacuum field. It provides users with the most reliable, safe and easy-to-use vacuum equipment products and high-quality professional services to help global customers and partners achieve success. The company's main products include: rotary vane vacuum pumps, screw vacuum pumps, Roots vacuum pumps, piston vacuum pumps, etc.

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business CHN

CHN