Oil-free vacuum pump: green and efficient, leading the new industrial trend

In today's rapidly developing industrial field, mechanical vacuum pumps are important auxiliary equipment, and their performance and environmental protection characteristics are increasingly valued. Oil-free vacuum pumps, with their unique advantages of operating efficiently without lubricating oil, are gradually becoming the first choice in many industrial fields. This article will deeply explore the working principle, application scope, advantages and disadvantages and operation methods of oil-free vacuum pumps, and especially introduce the innovative application of LeyNow vacuum system in this field.

Working principle: driven by technology, accurate and efficient

The working principles of oil-free vacuum pumps are diverse, mainly including volume change, mechanical rotation speed and low temperature capture. The volume-changing oil-free vacuum pump realizes periodic changes in volume through movable mechanical parts, thereby sucking in air when the volume increases and discharging air when the volume decreases. This principle requires extremely small gaps and extremely high precision between mechanical components to ensure efficient and stable vacuum extraction. The mechanical rotation speed type relies on extremely high mechanical rotation speed to directionally impact and carry away air molecules to achieve a vacuum effect. The low-temperature capture type uses a cold surface close to absolute zero to freeze and capture almost all air molecules to achieve a vacuum state.

Scope of application: extensive coverage, assisting industrial upgrading

Oil-free vacuum pumps are widely used in many fields due to their unique advantages. On the automatic packaging line, it can realize vacuum suction, bag opening and loading, improving production efficiency. In printing machinery, the vacuum suction of paper relies on the precise control of oil-free vacuum pumps. In addition, oil-free vacuum pumps are also widely used in liquid filling, vacuum molding of plastic products, air tightness testing, label pasting, photographic plate making, gas analysis, medical machinery, container leak detection, food processing and hospital operating rooms, etc. fields.

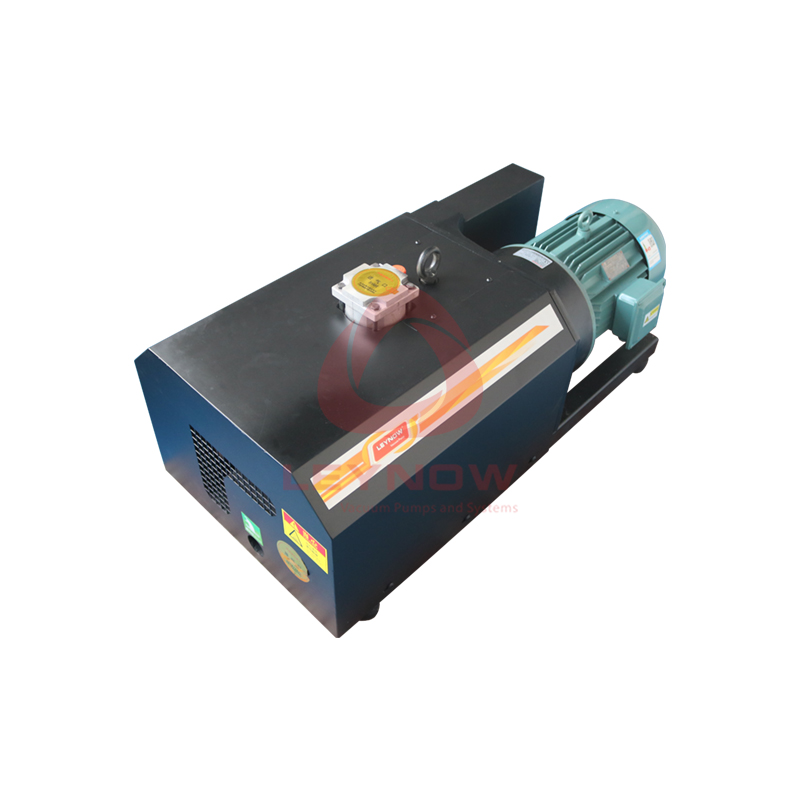

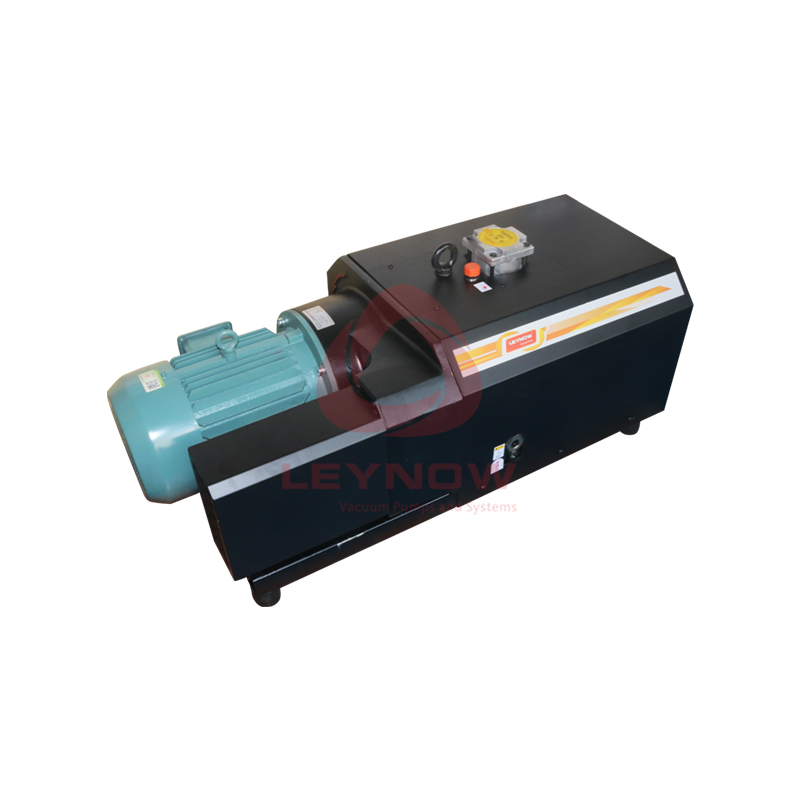

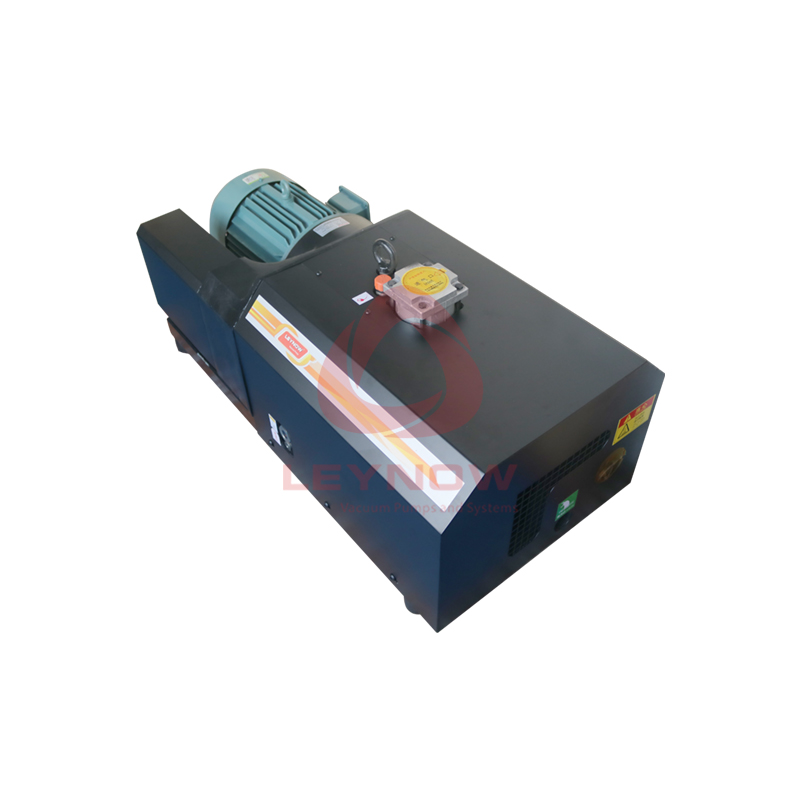

Innovative applications of LeyNow vacuum systems

In the application of oil-free vacuum pumps, LeyNow vacuum system has won wide recognition in the market for its excellent performance and innovative solutions. The LeyNow vacuum system adopts advanced oil-free technology, which not only ensures the purity of the vacuum extraction process, but also reduces safety risks during use. In the pharmaceutical machinery automatic line, the LeyNow vacuum system achieves efficient and stable pharmaceutical packaging through precise control. In food processing machinery, the LeyNow vacuum system effectively avoids contamination of food by lubricating oil and ensures food safety and hygiene. At the same time, the LeyNow vacuum system also reduces noise and vibration through optimized structural design, providing users with a more comfortable working environment.

Analysis of advantages and disadvantages: comprehensive understanding and rational choice

The advantages of oil-free vacuum pumps are obvious. It is pollution-free, ensuring the purity of the process or experiment; it is highly safe, avoiding fires and explosions caused by oil leakage or oil ignition; it is simple to maintain, reducing downtime and repair time, and improving work efficiency; It has good operating stability, is made of wear-resistant materials, has strong corrosion resistance, and can adapt to various environments and gases; it is energy-saving and environmentally friendly, and does not need to consume energy to drive the lubrication system.

However, oil-free vacuum pumps also have some limitations. It will generate a high temperature when running and needs to be dissipated through external cooling, otherwise the service life may be affected. In addition, the extraction capacity of oil-free vacuum pumps is relatively low and cannot meet some applications that require high vacuum levels. Compared with traditional lubricated vacuum pumps, oil-free vacuum pumps are more expensive, which may increase investment costs. At the same time, the vibration and air flow generated during operation will generate noise, which may interfere with some environments that have lower noise requirements.

Operation method: standardize the process and ensure safety

The operation method of oil-free vacuum pump needs to follow certain standardized procedures. First, conduct a comprehensive inspection, including whether the pump body, impeller and other components are intact, and whether the power plug and power switch are normal. For vacuum pumps with filters, it is also necessary to check whether the filters are clean to avoid clogging. Secondly, correctly connect the oil-free vacuum pump to the vacuum system to ensure that the connection is well sealed to avoid air leakage. Check all connecting pipes, valves, gaskets and other components to ensure that the connections are tight and there is no air leakage. Then, turn on the power and confirm that the power of the oil-free vacuum pump is turned on and the equipment is in normal working condition. Next, press the power switch of the oil-free vacuum pump to start the device. For vacuum pumps with control panels, relevant systems (such as cooling systems) must be turned on in sequence according to the instructions in the operation manual. If the oil-free vacuum pump has adjustable parameters (such as vacuum degree, pumping time, etc.), the required parameters need to be set on the operation interface. Finally, slowly open the valve connected to the oil-free vacuum pump and start vacuuming.

Conclusion: Green leadership, creating a better future together

Oil-free vacuum pumps are gradually becoming the first choice in the industrial field due to their non-pollution, high safety, simple maintenance, good operational stability, energy saving and environmental protection. As a leader in this field, LeyNow vacuum system provides efficient and stable vacuum extraction services to many industries with its excellent performance and innovative solutions. In the future, with the continuous development of science and technology, the performance of oil-free vacuum pumps will be further improved and the application fields will be wider. We look forward to more outstanding companies like LeyNow Vacuum Systems that can continue to innovate and lead the industry to develop in a greener, more efficient, and smarter direction.

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business CHN

CHN