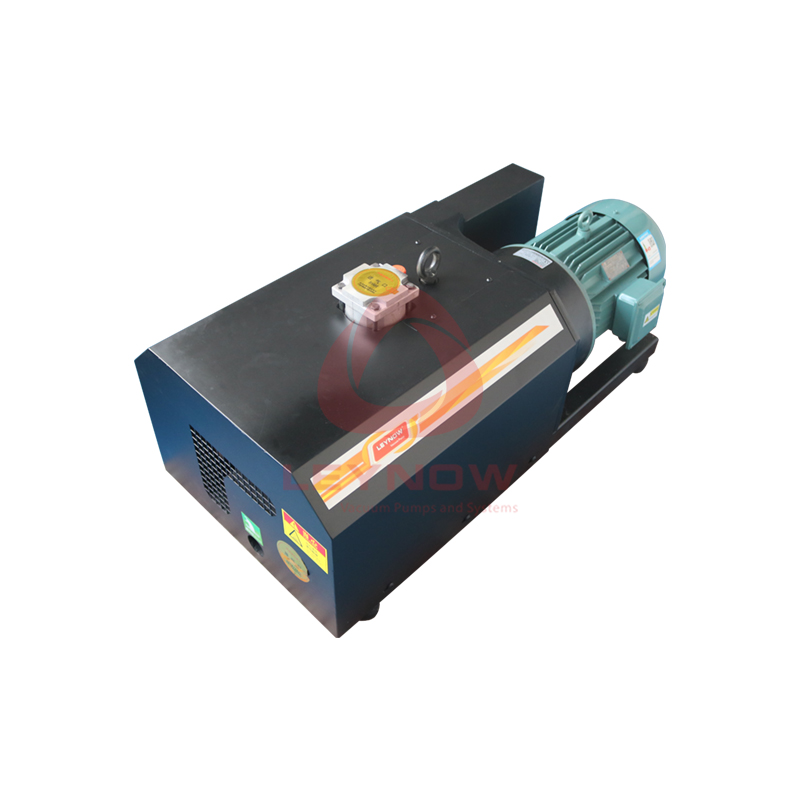

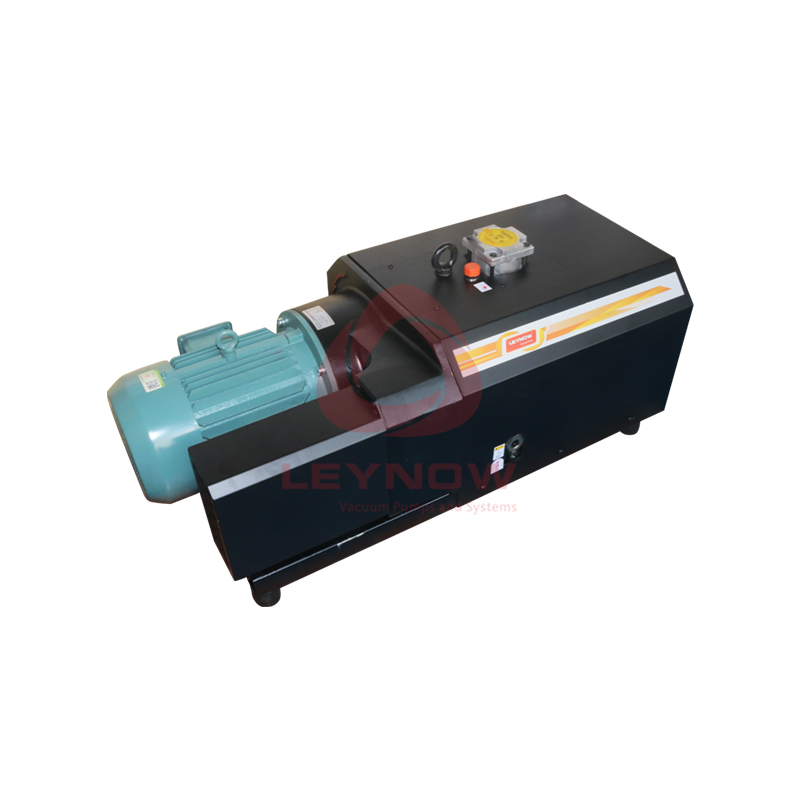

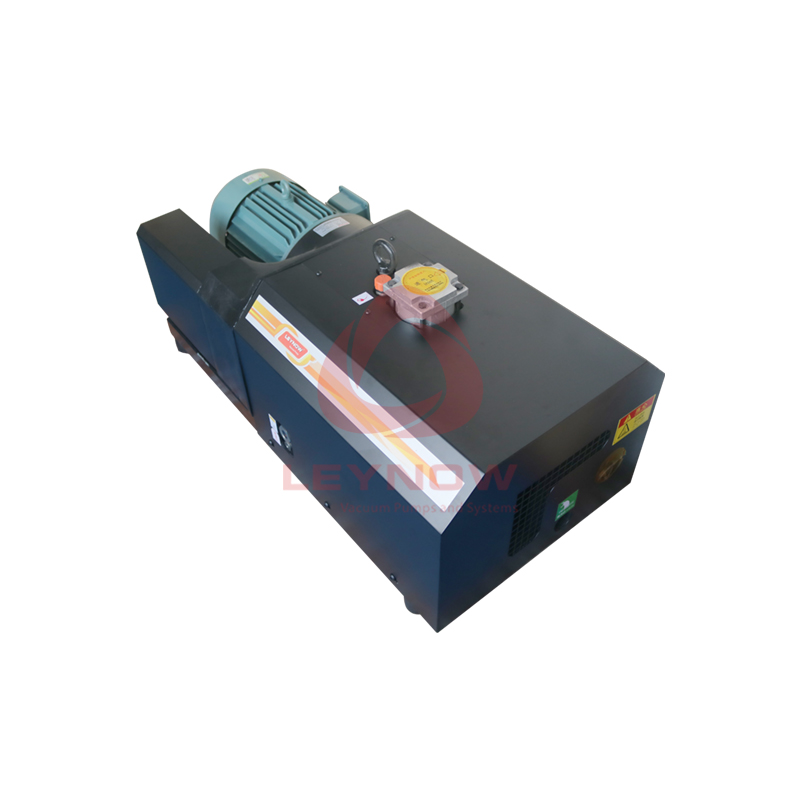

The application of gas ballast valves in rotary vane vacuum pumps and the leading practice of LeyNow vacuum systems

In the fields of modern industry and scientific research, vacuum technology is used everywhere, from semiconductor manufacturing to materials science, from food processing to medical technology, the vacuum environment provides the necessary conditions for countless precision processes. In these applications, rotary vane vacuum pumps have become indispensable equipment due to their simple structure, easy maintenance, and high pumping efficiency. However, in the face of complex gas environments containing condensable gases, traditional rotary vane vacuum pumps often face challenges. In order to overcome this problem, the emergence of gas ballast valve technology has opened up a new way to improve the performance of vacuum pumps. This article will deeply discuss the working principle, type and application of gas ballast valves in rotary vane vacuum pumps, and especially introduce the innovative practice of LeyNow vacuum system in this field.

Gas ballast valve: the intelligent guardian of rotary vane vacuum pumps

Gas ballast valve, as an important accessory of rotary vane vacuum pump, is originally designed to solve the problem of condensable gas condensing in the pump. During the working process of the vacuum pump, when the pumped gas contains condensable gases such as water vapor and organic solvent vapor, these gases will reach the saturated vapor pressure due to the increase in pressure during the compression process, and then condense into liquids and mix into the pump. in oil. This will not only reduce the pumping efficiency of the pump, but also accelerate the deterioration of the pump oil and affect the stable operation of the vacuum system.

The working principle of a gas ballast valve is to incorporate a certain amount of permanent gas (usually dry air at room temperature) into the compressed gas through the gas ballast hole during the compression process. The advantage of this is that before the partial pressure of the condensable gas reaches the saturated vapor pressure at the pump temperature, the total pressure of the mixed gas is enough to push open the exhaust valve, thereby expelling the condensable gas from the pump together with the permanent gas. outside. This process effectively avoids the condensation of condensable gas in the pump, protects the pump oil, and extends the service life of the pump.

Innovative applications of LeyNow vacuum systems

In terms of the research, development and application of gas ballast valve technology, LeyNow vacuum system is undoubtedly at the forefront of the industry. As a leader in vacuum technology, LeyNow is not only committed to improving the basic performance of vacuum pumps, but also investing a lot of energy in the design and optimization of gas ballast valves.

The gas ballast valve of the LeyNow vacuum system adopts an advanced combination design of throttle valve and check valve, which can accurately control the flow and pressure of the mixed gas, ensuring that it can effectively prevent condensability without affecting the ultimate vacuum degree of the pump. Condensation of gases. In addition, LeyNow has also developed an intelligent control system that can automatically adjust the opening degree of the gas ballast valve and the flow rate of the mixed gas based on real-time monitoring of gas composition and temperature data in the pump chamber, realizing the intelligence and automation of the gas ballast process.

In specific application scenarios, such as vacuum drying processes in semiconductor manufacturing, the gas ballast valves of LeyNow vacuum systems have demonstrated excellent performance. When extracting humid air containing a large amount of water vapor, LeyNow's gas ballast valve can respond quickly to ensure that water vapor does not condense in the pump, thereby protecting the pump oil and maintaining efficient pumping performance. At the same time, LeyNow's gas ballast valve also has the function of purifying the pump oil. When the pump oil is contaminated by a small amount of condensate, you only need to open the gas ballast valve and pump air for a period of time, and the pump oil can restore its original performance, greatly reducing the cost. Maintenance costs.

Types and applicable scenarios of gas ballast valves

Gas ballast valves can be divided into three categories: manual gas ballast valves, electric gas ballast valves and pneumatic gas ballast valves according to their different control methods and application scenarios.

1. Manual gas ballast valve: It requires manual rotation or pushing of the valve core to control the flow and cutoff of gas. This type of gas ballast valve is relatively simple to operate and is suitable for situations that do not require high levels of automation or require precise manual control or intermittent operation. For example, in some small vacuum experimental equipment, or when fine adjustment of the gas ballast function is required during debugging and maintenance, manual gas ballast valves have become an ideal choice.

2. Electric gas ballast valve: Automatic control of the valve is realized through electric actuators such as motors or electromagnets. Electric gas ballast valves have the advantages of convenient and fast operation, high control accuracy, and fast response speed. They can automatically adjust the gas flow according to the needs of the system. Electric gas ballast valves are particularly widely used in large vacuum systems that require a high degree of automation, such as large industrial vacuum production lines and automated vacuum processing equipment. The electric gas ballast valve of LeyNow vacuum system has demonstrated excellent performance in these fields with its intelligent control system and precise flow adjustment capability.

3. Pneumatic gas ballast valve: uses compressed air as the power source and controls the opening and closing of the valve through a pneumatic actuator. Pneumatic gas ballast valves are explosion-proof, safe and reliable, and are suitable for some hazardous environments with high explosion-proof requirements, such as vacuum systems in chemical, petroleum, natural gas and other industries. At the same time, pneumatic gas ballast valves have a simple structure, low maintenance costs, and can operate stably in some harsh working environments. The pneumatic gas ballast valve of the LeyNow vacuum system uses high-quality materials and precise manufacturing processes to ensure its reliable operation in harsh environments.

Precautions and operational suggestions

● When using a vacuum pump with a gas ballast valve, you need to pay attention to the following points:

1. Start-up and shutdown: When the mechanical pump starts to work, the gas ballast valve should be opened first to exclude condensable gas. Wait until it is basically extracted, then close the gas ballast valve. This can prevent atmospheric air from leaking into the suction end of the pump and affecting the pumping speed and ultimate vacuum degree of the pump.

2. Flow control: Control the flow rate of the mixed gas by adjusting the throttle valve of the gas ballast valve. Too large or too small flow rate will affect the gas ballast effect and equipment performance. Therefore, the flow value should be reasonably set based on the actual gas composition and working environment. The intelligent control system of the LeyNow vacuum system can automatically complete this process, greatly simplifying the operation difficulty.

3. Maintenance and maintenance: Regularly check the working status and sealing performance of the gas ballast valve. If there is leakage or damage, it should be replaced or repaired in time. At the same time, keeping the pump oil clean and replenishing it in an appropriate amount is also an important measure to ensure the normal operation of the gas ballast valve and extend the life of the equipment.

4. Intelligent application: For gas ballast valves equipped with intelligent control systems, their functional advantages should be fully utilized. Through real-time monitoring and data analysis, the working parameters and control strategies of the gas ballast valve are optimized to improve the overall performance and stability of the equipment. The intelligent control system of the LeyNow vacuum system provides strong support in this regard.

The emergence and development of gas ballast valve technology provides a strong guarantee for the application of rotary vane vacuum pumps in complex gas environments. As a leader in the industry, LeyNow vacuum system has pushed gas ballast valve technology to new heights through continuous innovation and optimization. In the future, with the continuous advancement of vacuum technology and the continuous expansion of application fields, gas ballast valve technology will continue to play an important role and contribute more to the innovation and development of vacuum technology.

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business CHN

CHN