Exploring the innovation path of oil-free vacuum pumps: advantage analysis and industry applications

In today's era of rapid technological development, vacuum pumps are basic equipment in many industrial and scientific research fields, and their technological progress is of immeasurable significance in promoting the development of the entire industry. Oil-free vacuum pumps, as an emerging technology in the field of vacuum pumps, have gradually emerged with their unique advantages and become the new favorite of the market. This article will deeply explore the technical principles, advantages and wide application of oil-free vacuum pumps in multiple industries, and especially introduce relevant application cases of LeyWow vacuum pumps to show their innovation path.

Technical principles and advantages of oil-free vacuum pumps

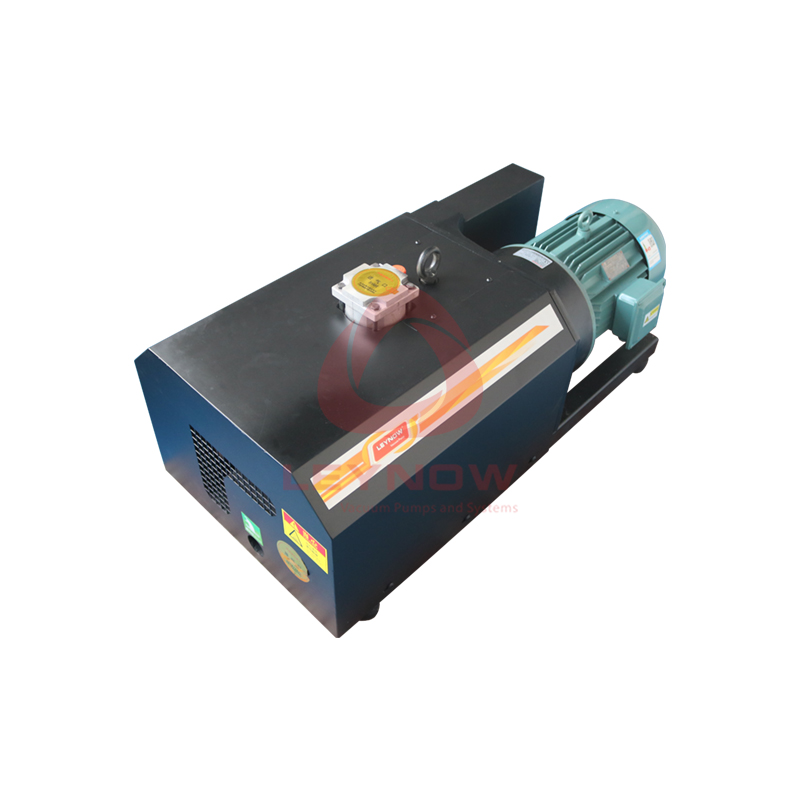

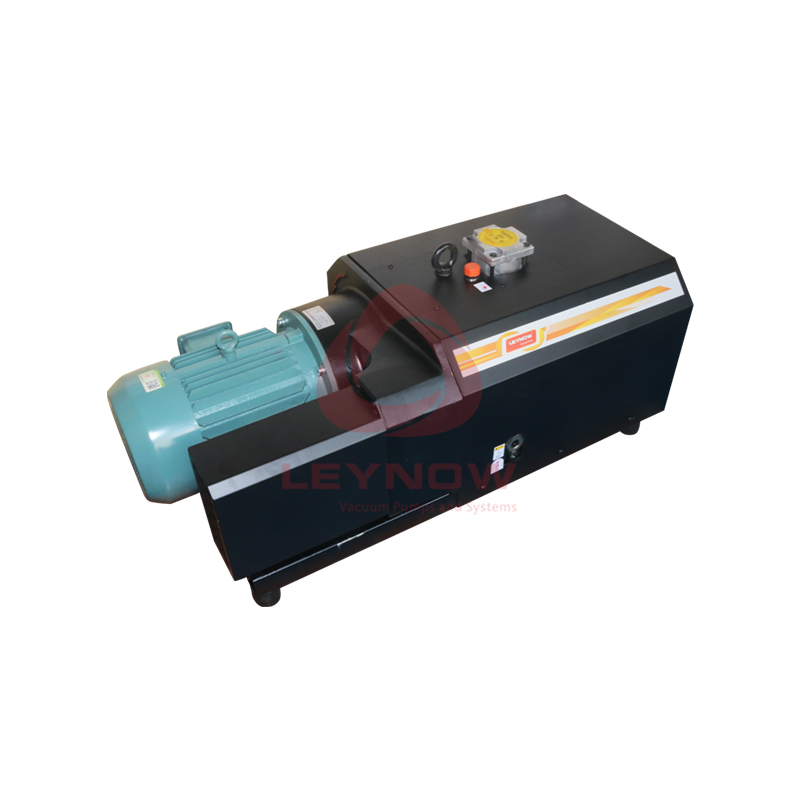

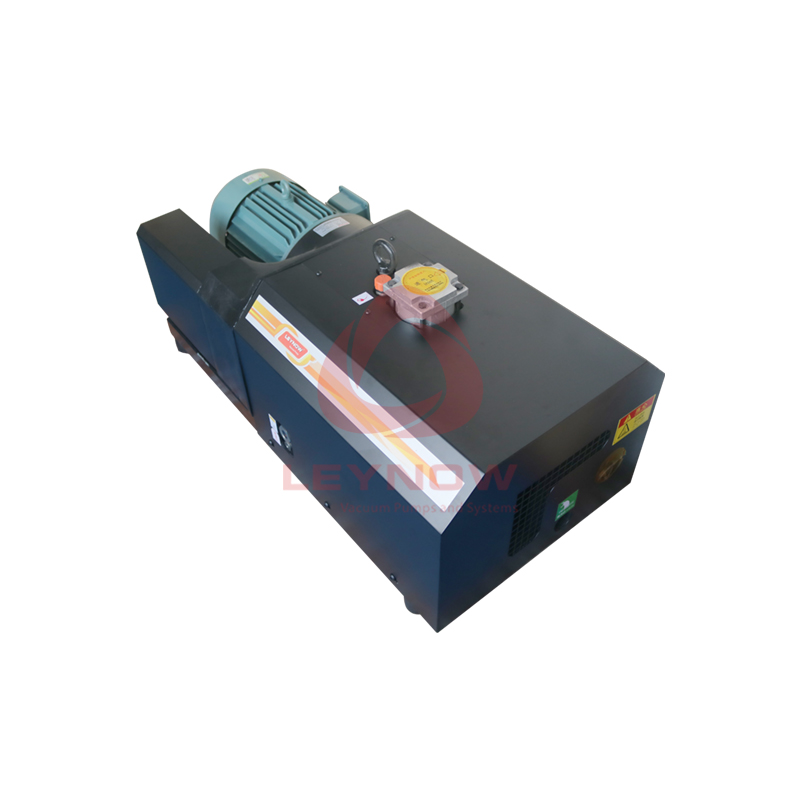

An oil-free vacuum pump is a mechanical vacuum pump that can operate without any oil for lubrication. Its working principle is similar to that of a general positive displacement pump, and it is composed of stator, rotor, rotary vane, cylinder, motor and other main parts. During the process of high-speed rotation, the rotary vanes in the rotor slot separate the pump chamber into multiple working chambers. Through the action of centrifugal force, the rotary vanes are close to the cylinder wall and separate the stator inlet and outlet, thereby realizing the suction and discharge of gas. discharge.

Compared with traditional oil-sealed vacuum pumps, oil-free vacuum pumps have the following significant advantages:

Clean and environmentally friendly: Oil-free vacuum pumps do not produce fumes during work and will not pollute the environment. This is particularly important for industries such as food and medicine that have extremely high cleanliness requirements. The oil-free feature enables it to provide a high-purity vacuum environment and meet the needs of processes that require high gas purity.

Easy maintenance: Since there is no need for lubricating oil, the maintenance work of the oil-free vacuum pump is greatly simplified, reducing the tedious steps of changing lubricating oil and cleaning up oil stains. This not only reduces maintenance costs, but also improves equipment operating efficiency.

Energy-saving and efficient: Oil-free vacuum pumps pay more attention to energy efficiency in design, and their energy consumption is usually lower than traditional oil-lubricated pumps, helping to reduce operating costs. This is undoubtedly a considerable saving for long-term operation of equipment.

Long life: The mechanical parts of the oil-free vacuum pump are specially treated to have higher wear resistance and corrosion resistance, thus extending the service life of the equipment. This is undoubtedly an important consideration for industrial scenarios that require long-term stable operation.

Silent operation: Oil-free vacuum pumps usually have low noise characteristics and are more suitable for use in places that require a quiet environment, such as laboratories, hospital operating rooms, etc.

Industrial applications of oil-free vacuum pumps

Oil-free vacuum pumps have been widely used in many industries due to their unique advantages. The following are some typical application scenarios:

pharmaceutical industry

In the pharmaceutical process, oil-free vacuum pumps are widely used in vacuum drying, vacuum filtration and other aspects. Since the pharmaceutical industry has extremely high requirements for product purity and quality, oil-free vacuum pumps can provide a high-purity vacuum environment to ensure that drugs are not contaminated during the production process. For example, in the production lines of traditional Chinese medicine extraction and western medicine preparations, oil-free vacuum pumps are used in vacuum distillation and vacuum concentration processes to improve product purity and stability.

food industry

In food processing, oil-free vacuum pumps also play an important role. It is widely used in vacuum packaging, vacuum freeze-drying and other processes to extend the shelf life of food and maintain the nutritional content of food. For example, in the packaging process of perishable foods such as meat and seafood, oil-free vacuum pumps can quickly remove the air in the package to form a vacuum environment, effectively inhibiting the reproduction of microorganisms, thereby extending the shelf life of food.

Semiconductor industry

In the field of semiconductor manufacturing, oil-free vacuum pumps are also indispensable. The semiconductor manufacturing process requires extremely high environmental cleanliness, and any tiny impurities may cause product performance degradation or even scrapping. Oil-free vacuum pumps can provide a clean and dust-free vacuum environment for semiconductor manufacturing, ensuring the smooth progress of key process links such as chip manufacturing and thin film deposition.

research laboratory

In the field of scientific research, oil-free vacuum pumps are also widely used. The oil-free feature enables it to provide a clean vacuum environment and is suitable for vacuuming experimental equipment and creating a more stable test environment. For example, oil-free vacuum pumps play an important role in magnetic material research, thin film deposition and other experiments in the fields of materials science, biomedicine and other fields.

Medical industry

In medical equipment, oil-free vacuum pumps are also widely used. For example, in medical equipment such as suction systems and artificial ventilators, oil-free vacuum pumps can provide efficient, safe and reliable vacuum suction and delivery functions. The oil-free feature avoids the impact of oil vapor on patients' health and improves the safety of medical equipment.

Application cases of LeyWow vacuum pumps

As a leader in the vacuum pump industry, LeyNow's oil-free vacuum pump products have been widely used in multiple industries and have won unanimous praise from users. The following are application cases of Leno vacuum pumps in several typical industries:

Pharmaceutical industry case

In the production process of a well-known pharmaceutical company, Leno oil-free vacuum pumps were used in the vacuum drying process of pharmaceuticals. The pharmaceuticals produced by this company have extremely high requirements for purity and quality, and traditional oil-sealed vacuum pumps are difficult to meet their needs. The LeyNow oil-free vacuum pump, with its high-purity vacuum environment and stable operating performance, has successfully solved the company's production problems and improved product quality and market competitiveness.

Food processing case

In the vacuum packaging production line of a large food processing company, Leno oil-free vacuum pumps are used for vacuum packaging of meat products. The company uses advanced vacuum packaging technology to extend the shelf life of products and maintain their nutritional content. LeyNow oil-free vacuum pump relies on its efficient pumping performance and stable operating performance.

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business CHN

CHN