Vacuum technology empowers new trends in cultural tourism: high-cold zero-carbon residence cabin shines at CIIE

In early January, the 7th China International Import Expo was held as scheduled in Shanghai. This globally acclaimed event attracted the active participation of countless domestic and foreign companies, and various cutting-edge technologies, innovative products and advanced business models competed to appear. Among the many exhibits, vacuum technology products have become a beautiful sight at this expo with their unique charm and broad application prospects. What is particularly eye-catching is that the high-cold zero-carbon cabin launched by a certain technology company in Sichuan not only demonstrates the excellent performance of vacuum technology in the field of thermal insulation and energy saving, but also sets a precedent for the deep integration of the vacuum industry and the cultural tourism industry.

At this Import Expo, vacuum products have become a highlight. From vacuum acquisition equipment to vacuum coating equipment to vacuum measuring instruments, there is a dazzling array of vacuum technology products, demonstrating the wide application of vacuum technology in modern industry. However, among these professional equipment, an alpine zero-carbon cabin that looks like a miniature house has attracted a large number of guests and merchants to stop and watch with its unique creativity and practical functions.

This alpine zero-carbon cabin is carefully built by a certain technology company in Sichuan, fully considering the climate characteristics of alpine regions. According to the relevant person in charge of the company, the cabin can be used normally in extreme environments of more than 4,000 meters above sea level and minus 40 degrees Celsius. This is due to its internal vacuum insulation technology and unique vacuum materials, which enable the product to have excellent insulation performance and energy-saving effects. It can easily achieve constant indoor temperature and provide residents with a comfortable and warm living environment.

Vacuum insulation technology: a model of technology changing life

Vacuum insulation technology, a term that is no stranger to daily life, has long been widely used in our daily necessities, such as vacuum cups, vacuum refrigerators, etc. The common feature of these products is that they can maintain the stability of the internal temperature within a certain period of time, providing us with convenience. So, how does vacuum insulation technology achieve this function?

In fact, the principle of vacuum insulation technology is not complicated. It is mainly based on the heat transfer principle in physics. We know that there are three main ways of heat transfer: heat conduction, heat radiation and heat convection. Vacuum insulated containers usually have a double-layer structure, and a vacuum is drawn between the two layers. This vacuum state effectively reduces the pathways for heat transfer, preventing heat from being lost to the outside world through these pathways, thereby achieving the effect of heat preservation.

In high-cold zero-carbon cabins, there are two main core applications of vacuum insulation technology: vacuum insulation panels and vacuum glass. The application of these two materials has greatly improved the thermal insulation performance of the cabin.

Vacuum insulation panels: the ultimate display of thermal insulation performance

Vacuum Insulation Panel (VIP) is a new type of super insulation material based on vacuum insulation technology. It combines the advantages of vacuum insulation and microporous insulation to achieve the ultimate thermal insulation effect. VIP is made of a porous nano-core material with good thermal insulation properties that is encapsulated with a high-barrier film in a vacuum state. This structure reduces heat conduction, heat convection and heat radiation to the greatest extent, and isolates heat transfer, thus having efficient heat preservation capabilities.

In high-cold zero-carbon cabins, vacuum insulation panels are used as core insulation materials, and their insulation performance has been greatly improved compared to traditional insulation materials, reaching 6 to 10 times. At the same time, the vacuum insulation panels also have Class A fire resistance, providing a strong guarantee for the safety of the cabin.

Vacuum glass: double protection of sound insulation and thermal insulation

In addition to vacuum insulation panels, vacuum glass is also an indispensable part of the high-cold zero-carbon cabin. Vacuum glass is a new type of energy-saving glass, which is composed of two or more pieces of flat glass. Supports with a diameter of 0.2mm are arranged in a square array between the glass plates, and low melting point solder is used to seal the two pieces of glass. One piece of glass has an air extraction port. After the vacuum is exhausted, it is sealed with a sealing sheet and low-temperature solder to form a vacuum cavity.

This unique structure gives vacuum glass excellent thermal insulation and sound insulation properties. Compared with conventional insulating glass, the thermal insulation performance of vacuum glass is improved by 2 to 4 times. At the same time, since sound cannot propagate in a vacuum, the sound insulation effect of vacuum glass is also improved by more than 30%. In the alpine zero-carbon living cabin, the application of vacuum glass not only improves the comfort of the living environment, but also provides residents with a quiet and private private space.

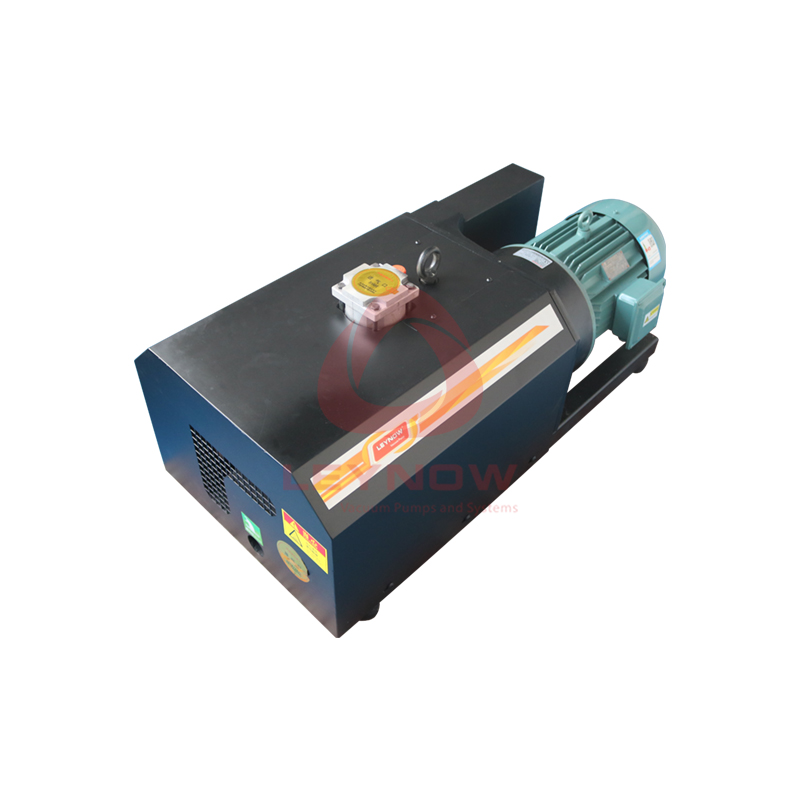

LeyNow Vacuum Pump: Helping a new leap forward in vacuum technology

In the process of building the alpine zero-carbon cabin, the LeyNow vacuum pump undoubtedly played an important role. As a leader in the field of vacuum technology, LeyNow vacuum pumps have won the trust and praise of many customers with their excellent performance and stable quality.

LeyNow vacuum pumps provide powerful vacuum extraction capabilities during the production of vacuum insulation panels and vacuum glass. By precisely controlling the degree of vacuum, the product's thermal insulation and sound insulation properties are ensured to be optimal. At the same time, LeyNow vacuum pumps also have the advantages of high efficiency, energy saving, and environmental protection, and meet the requirements of modern industry for green and sustainable development.

It is worth mentioning that LeyNow vacuum pumps not only play an important role in high-cold zero-carbon living cabins, but are also widely used in other fields. Such as semiconductor manufacturing, food processing, pharmaceutical manufacturing, etc., providing strong support for the application of vacuum technology in these fields.

Vacuum and cultural tourism "CP": opening a new chapter in industrial development

The successful debut of the high-cold zero-carbon residential cabin not only demonstrates the excellent performance of vacuum technology in the field of thermal insulation and energy saving, but also provides useful exploration for the deep integration of the vacuum industry and the cultural tourism industry. This innovative practice not only enriches the application scenarios of vacuum technology, but also injects new vitality into the high-quality development of the cultural tourism industry.

With the improvement of people's living standards and changes in consumption concepts, the cultural tourism industry is facing unprecedented development opportunities. The application of vacuum technology undoubtedly provides more possibilities for the high-quality development of the cultural tourism industry. For example, constant-temperature swimming pools and constant-temperature bathrooms created through vacuum technology can provide tourists with a more comfortable and convenient travel experience. At the same time, vacuum technology can also be used in energy-saving renovation and environmental protection management of scenic spots to promote the green and sustainable development of the cultural tourism industry.

Just like the concept upheld by a certain technology company in Sichuan - "serve a better life with vacuum technology", vacuum technology is bringing more convenience and beauty to our lives with its unique charm and wide application prospects. As an innovator in the field of vacuum technology, LeyNow vacuum pumps will continue to facilitate the deep integration of vacuum technology with other industries and promote the high-quality development of new productivity.

Looking to the future, with the continuous innovation of vacuum technology and the continuous expansion of application fields, the vacuum industry will usher in broader development prospects. At the same time, we also hope that more companies, like a certain technology company in Sichuan, will have the courage to explore and innovate, and contribute to the development of the vacuum industry. I believe that in the near future, vacuum technology will bring more surprises and changes to our lives.

In addition, the deep integration process between the cultural tourism industry and vacuum technology requires the joint efforts of governments, enterprises, scientific research institutions and other parties. The government should increase support for the research and development and application of vacuum technology and promote the deep integration of vacuum technology with the cultural tourism industry. Enterprises should strengthen technological innovation and product research and development, and continuously improve the application level of vacuum technology in the cultural tourism industry. Scientific research institutions should strengthen basic research and technical research to provide strong support for the development of vacuum technology.

In short, the deep integration of vacuum technology and the cultural tourism industry not only provides new opportunities and challenges for the development of the vacuum industry, but also injects new impetus into the high-quality development of the cultural tourism industry. We have reason to believe that with the joint efforts of all parties, the integrated development of vacuum technology and the cultural tourism industry will achieve more significant results and bring more beauty and convenience to our lives.

(Note: The "LeyNow vacuum pump" in this article is only an example, and actual applications may involve different vacuum pump brands or models.)

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business CHN

CHN