Degassing of liquids, pastes and high-moisture products is one of the most important applications of modern vacuum processes in many industry sectors. The use of vacuum technology to remove gas, steam and moisture from processed products is beneficial to improving product quality.

Degassing during plastic extrusion is one example. The vaporized water and gas distilled from the melting of the plastic are directly extracted from the extruder screw area, greatly improving the structure and physical properties of the product.

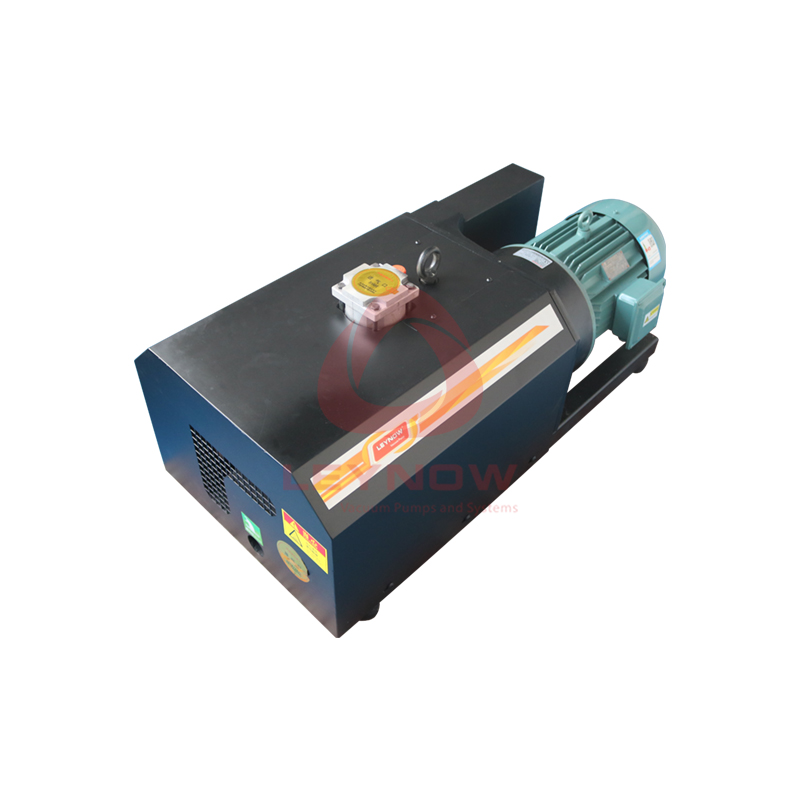

We offer a range of standardized vacuum pump systems dedicated to the extrusion process, equipped with separators or filtration devices for condensing or separating water vapor or process gases in the extruder. Our project engineers will consider your requirements and recommend a vacuum system that is precisely matched to your extruder capacity and raw material type.

Advantages

Degassing of liquids, pastes and high-moisture products is one of the most important applications of modern vacuum processes in many industry sectors. The use of vacuum technology to remove gas, steam and moisture from processed products is beneficial to improving product quality.

Degassing during plastic extrusion is one example. The vaporized water and gas evaporated from the melting of the plastic are directly extracted from the extruder screw area, greatly improving the structure and physical properties of the product.

We offer a range of standardized vacuum pump systems dedicated to the extrusion process, equipped with separators or filtration devices for condensing or separating water vapor or process gases in the extruder. Our project engineers will consider your requirements and recommend a vacuum system that is precisely matched to your extruder capacity and raw material type.

Vacuum degassing

We provide vacuum solutions for all degassing processes. Customers can rely on our high-quality products and decades of experience in degassing. We offer a wide range of vacuum pumps for degassing applications in food production, which can be optimized for any process and meet the highest hygiene standards.

Degassing of pastes and wet materials

The food industry uses vacuum degassing to remove air from products such as pasta products, ketchups, fish sauces, sauces, mayonnaise, mustards and jams. The degassing process usually takes place before packaging and can be integrated into the mixer, drum, extruder or evaporator line. The vacuum degassing process removes oxygen from the finished product, thereby extending storage time. In addition, product structure and consistency can be improved, especially for pasta products. The process is fast, energy-saving and basically maintenance-free. The screw vacuum pump operates without water or oil, which eliminates the possibility of product contamination and is the most ideal choice.

Plastic degassing

Plastic extrusion is a common process in the plastics industry, the purpose of which is to melt, mix and homogenize plastic. First, the pellets, powder or bead-like raw materials are transported through a screw in a heated drum. Next, the plastic melts into a viscous liquid under the action of friction and heat, and is then put into a mold and pressurized to finally form. Before the plastic is placed in the mold, a vacuum must be applied to remove air bubbles that can cause holes or other defects in the finished product. We offer a range of Plastex vacuum systems specifically designed for degassing plastic extruders. Our project engineers will select the appropriate model based on your specific application, materials and production capabilities.

Seawater degassing

Secondary recovery through water injection is a major feature of crude oil production and a key factor in achieving and maintaining productivity where economically feasible. The water used here must be degassed to remove the oxygen content, as oxygen has a detrimental effect on the desulfurization system. Today, vacuum degassing is the most common method used in the oil and gas industry: packed towers are constantly swept through a vacuum system to remove oxygen and other gases. Generally, two-stage mass transfer packing is used.

Mineral water degassing

Producers of mineral water and other beverages require precise amounts of dissolved carbon dioxide in their products, but the amount of carbon dioxide in the source water may vary. Solving this problem requires multiple processes: first, use a vacuum degassing system to remove carbon dioxide from the source water, then cool and dissolve it, and finally add a certain amount of carbon dioxide back into the finished product during the bottling stage. This ensures consistent product quality. Screw vacuum pumps operate without water or oil, eliminating the possibility of product contamination and making them ideal for degassing systems for mineral water and other beverages.

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business CHN

CHN