Compressor application

power loom

Usually power looms use a small amount of air. Those used for denim spinning or operating medium-sized PFY installations require 500 - 1,500 cfm of air. Large integrated facilities and texturing units require the highest air volumes, between 2,000 - 40,000 cfm.

Gardner Denver not only manufactures and supplies reciprocating and screw compressors, air handling systems and automatic monitoring technology to meet all of the above air needs, but also continuously develops the latest compressor products, which have proven to be a wise investment.

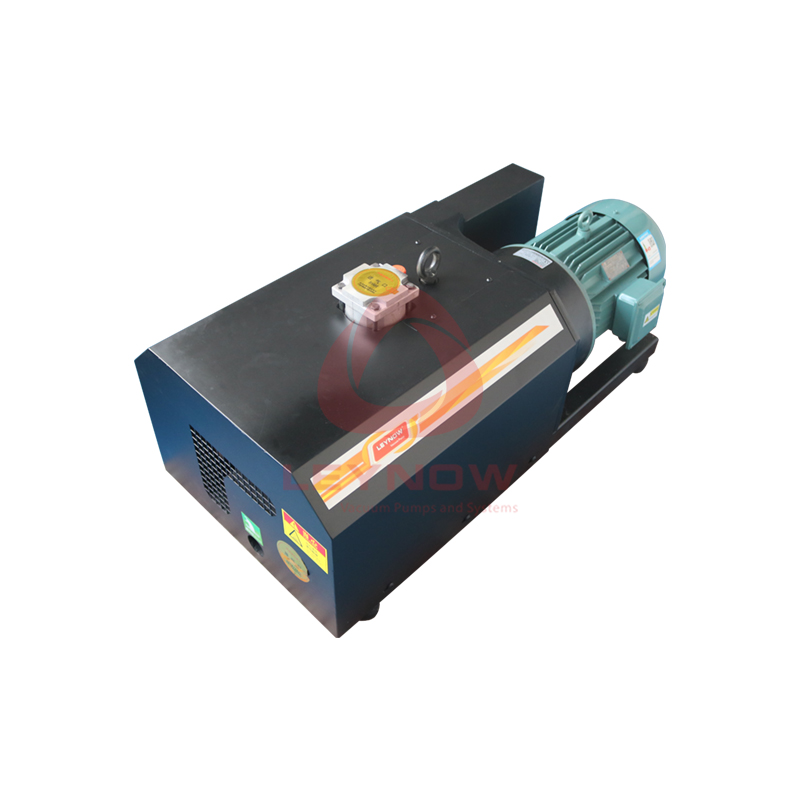

Blower and vacuum applications

Draining dyed carpets

Carpets must be cleaned with clean water after dyeing. During this process, the carpet is soaked in water and must be gently removed from the water using economical methods.

For this purpose, an adjustable suction trough is used to feed the carpet into a suction roller. A vacuum pump connected to the suction roller draws out the air in the tank, thereby removing about 80% of the water remaining in the carpet. Continuous airflow ensures careful material handling. Easily drains ongoing water flow and then drains along with the working fluid.

cutting table

In order to facilitate the processing and positioning of many rolls of fabric, an air cushion is formed on the cutting table through a perforated plate. Once a roll of fabric is positioned, the vacuum holds the fabric in proper processing position on the cutting table.

knitting machine

Textile fabrics become dirty when weaved by textile machinery. The dirt is extracted into the reservoir by the vacuum of the side flow blower.

Air powered loom

In order to facilitate the replacement of weft yarn spindles, the thread ends on the weft yarn spindles stacked in the storage table are automatically pulled in and tensioned. Once all the yarn on the weft spindle is used up, the thread ends are cut and drawn out into the thread container in front of the blower. After finishing the weaving process, vacuum the edges of the fabric to prevent remaining threads from being dragged into the container.

Sock knitting machine

During the knitting process, compressed air is applied to hold the finished sock section within the sock cylinder so that the knitting needles can move freely. Use a vacuum cleaner to remove messy threads. After knitting is completed, the socks are sucked out of the cylinder and placed into the container through a compressed air pipe connected to the receiving container of each knitting machine.

Yarn steam treatment

Yarn in a spinning machine is wound around a spool, causing the yarn to form a spiral. However, for further processing of the yarn, the yarn must be straight. Therefore, a steam treatment is applied to the yarn, breaking up the arrangement of the material's molecules and smoothing out the fiber structure.

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business CHN

CHN