Advantages

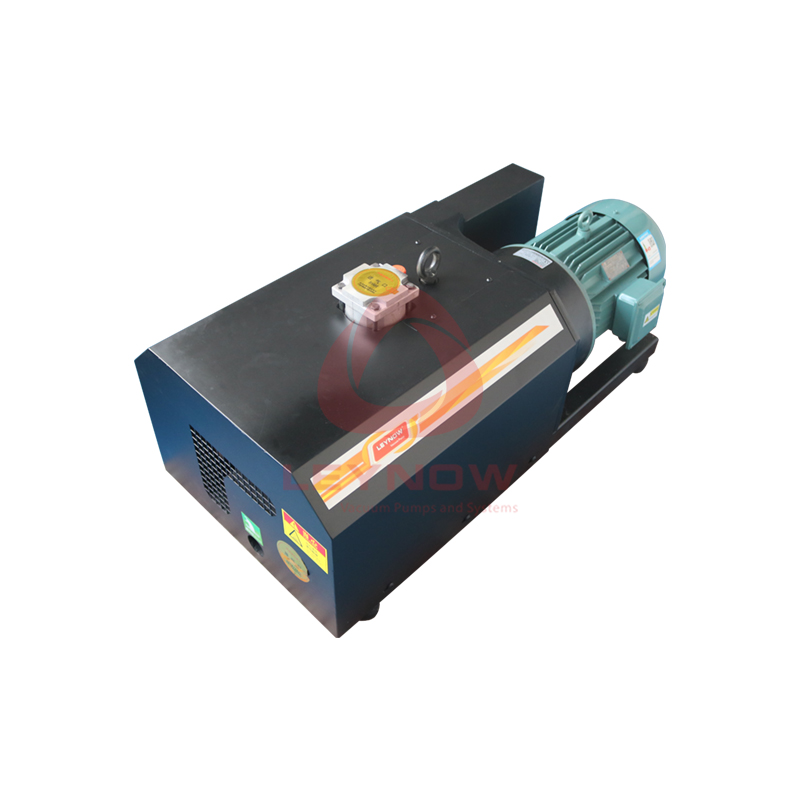

LeyNow offers a comprehensive range of vacuum pumps and accessories to meet the highest vacuum system requirements for heat treatment applications.

Application requirements in the field of heat treatment

LeyNow offers a comprehensive range of vacuum pumps and accessories to meet the highest vacuum system requirements for heat treatment applications.

Quenching and Tempering

Quenching and tempering require a vacuum system with strong steam drainage capability. LeyNow's SOGEVAC and TRIVAC series products combined with Roots pumps can provide a complete solution for this application.

Vacuum brazing

Acidic flux may evaporate during the soldering process and enter the vacuum system, causing the oil seal pump to malfunction. Leybold DRYVAC and LEYVAC series screw pumps can fully meet the application requirements of vacuum brazing. Leno also offers a complete range of high vacuum products for brazing applications. The DIP series diffusion pumps with energy-saving functions are market benchmarks. LeyNow's cryogenic pumps and turbomolecular pumps are widely used in hydrocarbon-free brazing.

Vacuum sintering

During the vacuum sintering and dewaxing process, the polymer binder evaporates and cracks into the vacuum pump and condenses inside the pump, which is a great challenge to the vacuum pump. Oil-sealed pumps perform poorly and require very frequent maintenance and service. Even dry pumps develop internal build-up over time and require periodic cleaning. The SCREWLINE series of screw pumps can be cleaned on site, making them the best choice for vacuum sintering applications.

Secondary refining and degassing process of molten steel

The vacuum degassing (VD) process is mainly used for alloy steel smelting; the vacuum oxygen decarburization (VOD) process is mainly used for stainless steel smelting. The VD treatment process is mainly used to remove the volatile atmosphere (such as hydrogen, oxygen, nitrogen, etc.) in the molten steel to enhance the performance of the steel. The VOD treatment process removes easily oxidized components (such as carbon, phosphorus, etc.) in the molten steel by injecting oxygen. RH/RH-OB (Ruhrstahl Heraeus) process: In integrated steel plants, the RH/RH-OB process is widely used to increase the production capacity of vacuum molten steel treatment. The RH/RH-OB degassing process is basically the same as the VD/VOD process. In the RH system, there are two suction nozzles at the bottom of the vacuum tank that are inserted into the ladle and immersed in the molten steel. When the vacuum tank is evacuated, the molten steel will be pressurized into the vacuum tank for degassing.

Vacuum degassing

The vacuum system must handle the entire air load and the large amount of dust generated after the molten steel is outgassed and condensed. Usually the required pumping speed at the degassing pressure (~0,67 mbar) is between 50,000 m³/h and 250,000m³/h. Required evacuation time: about 4-6 min. Since the molten steel will continue to cool during the degassing process, rapid evacuation is very important. In order to avoid "slag overflow", it is usually necessary to control the evacuation process.

Vacuum brazing

Acidic flux may evaporate during the soldering process and enter the vacuum system, causing the oil seal pump to malfunction. Leybold DRYVAC and LEYVAC series screw pumps can fully meet the application requirements of vacuum brazing. Leybold also offers a complete range of high vacuum products for brazing applications. The DIP series diffusion pumps with energy-saving functions are market benchmarks. Leybold's cryogenic pumps and turbomolecular pumps are widely used in hydrocarbon-free brazing.

Vacuum sintering

During the vacuum sintering and dewaxing process, the polymer binder evaporates and cracks into the vacuum pump and condenses inside the pump, which is a great challenge to the vacuum pump. Oil-sealed pumps perform poorly and require very frequent maintenance and service. Even dry pumps can develop internal build-up over time and require periodic cleaning. The SCREWLINE series of screw pumps can be cleaned on site, making them the best choice for vacuum sintering applications.

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business CHN

CHN