Advantages

Food packaging and processing

With changes in social consumption habits and increased emphasis on food safety, vacuum technology is increasingly used in the fields of packaging and food processing. Food processing covers a wide range of applications and vacuum is often used in packaging for different characteristics. Vacuum plays a key role in packaging processes and packaging production in general. Packaging forming, thermoforming and coating can be carried out efficiently and accurately using vacuum technology. In addition, vacuum technology can be used for moving, transporting, unpacking and sealing. During the packaging process, the items to be packed can also be fed in and embedded firmly with the help of vacuum. The use of vacuum technology in the food packaging process helps keep food fresh for longer – without compromising its quality. Fresh food uses MAP (modified atmosphere packaging technology) to maintain the appearance, freshness and taste of the food.

Food packaging

By reducing the residual oxygen concentration, the growth of aerobic bacteria is limited, so that the storage period can generally be extended by 5 to 10 times. In addition, vacuum packaging can prevent the evaporation of ingredients to maintain the original flavor and texture. It can also reduce surface dehydration and hardening caused by dry and cold air flow, and prevent secondary pollution during transportation.

●Chamber Packaging Machines: Chamber packaging machines can be of single or double chamber type, with or without belt conveyors.

●These models operate on a cyclic basis, pumping approximately 1 mbar from atmospheric pressure every 0.5 - 2 minutes.

●Typical vacuum system: circular rotary large bag packaging machine.

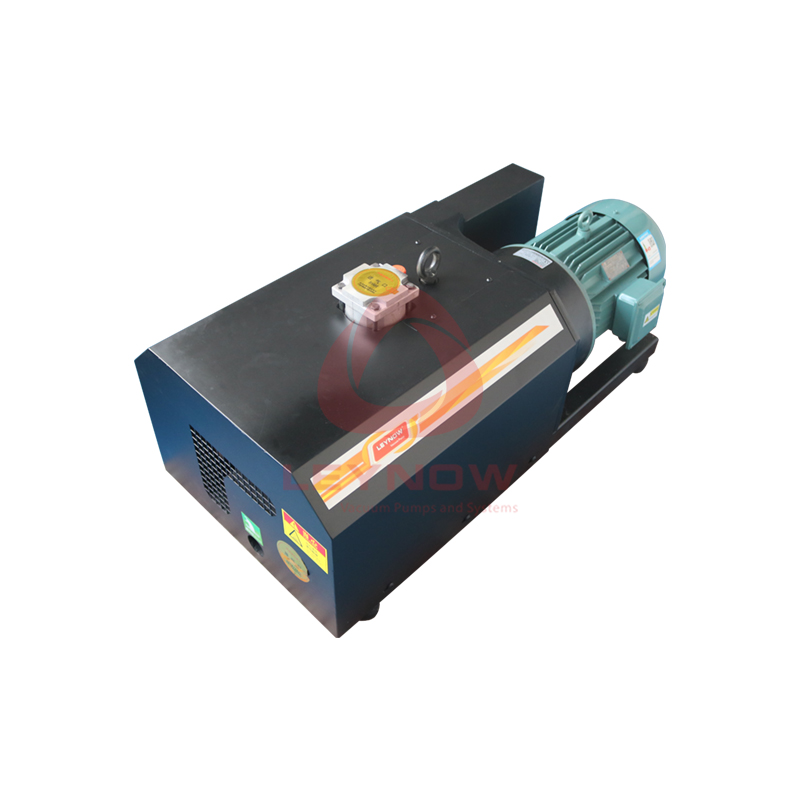

●If the backing vacuum pump is located far from the machine, an optional single-stage rotary vane pump or dry pump can be combined with a Roots pump.

Modified atmosphere fresh-keeping packaging

MAP modified atmosphere packaging includes two steps: evacuation and inflation. According to different needs, there will be one or more cycles of pumping and inflating to fill the bag with a protective atmosphere.

Usually there are the following types:

●High concentration of oxygen (O2) keeps red meat foods bright, preserving both quality and freshness.

●Nitrogen (N2) is mainly used to fill the packaging volume and is not easy to react, such as packaging protection during transportation of fragile food.

●Carbon dioxide (CO2) reacts with water to form carbonic acid, whose pH value is acidic. This environment can inhibit the growth of microorganisms.

Typical vacuum system: single-stage rotary vane pump or dry screw pump, combined with Roots pump. In the case of oxygen reinjection, it may be necessary to use special vacuum pumps (hydrocarbon-free, with inert oil, explosion-proof vacuum pumps), which are commonly used in red meat packaging to enhance the red color, and oxygen-compatible sealing materials.

MAP Bulk Packaging: Often referred to as "Snorkle machines" or "Vacuum probe machines", these machines allow for the simultaneous modified atmosphere packaging of multiple sachets or large bulk bags of food. After the air is extracted, a mixture of O2 and CO2 gases is introduced into the bag (controlled atmosphere) and then automatically heat sealed.

Typical vacuum pump pumping speeds are single stage 10 to 65 m3. h-1

Thermoforming/Stretch Film Packaging Machine

All types of products can be packed continuously via plastic film on two reels or pre-formed trays. The lower film is heat-formed and blistered into a tray container, and the upper film covers the tray and is heat-sealed to isolate the environment.

The film is positioned over the thermoformed container and then heat-sealed to isolate the product from ambient air. The product is packaged in skin-fitting packaging or modified atmosphere packaging. In both cases a vacuum is necessary.

The film is fed over a forming mold, where heat and vacuum are used to form the food container (thermoforming). After the container is quickly cooled, the food is placed in the container and sent to the sealing mold, which is evacuated and heated to achieve sealing between the upper film and the container.

Typical vacuum pump pumping speeds range from 20 to 6,000m3/h in a single stage. Hokaido's related products include oil-type rotary vane vacuum pumps, dry screw vacuum pumps and Roots vacuum pumps.

Typical vacuum system: Central vacuum system consisting of a rotary vane pump or a dry pump.

Bag-feeding automatic packaging machine

The bag-type automatic or semi-automatic packaging machine replaces the original manual packaging. The operator only needs to place hundreds of bags at the bag picking place of the equipment at one time, and the equipment will automatically take the bags, print the date, open the bags, and weigh. Blanking, evacuation, sealing, output and other operations.

Food processing

Food processing refers to all processes that transform raw materials into food or convert food into other forms, such as clean produce or slaughtered livestock, into attractive, marketable and long-lasting food products. Similar processing techniques are used in the production of animal feed.

Food processing covers a wide range of applications and vacuum is often used for various special requirements.

Slaughterhouse application: removal of bone marrow, offal, poultry offal, removal of special hazardous materials (SRM), etc. In many slaughterhouses (such as cattle and pigs), vacuums are used to remove offal and remove fat and other useless parts. In this process, a pump operates continuously under low vacuum like a vacuum cleaner, recycling fat, offal or target product into a container. Sometimes, vacuum and steam are used together in order to reduce bacterial counts (steam significantly kills bacteria). Bone marrow ablation systems also use a vacuum. The need to remove bone marrow before carving up animals is a new measure taken by slaughterhouses after the mad cow disease crisis to prevent, control and eliminate mad cow disease in livestock over one year old.

Vacuum pre-cooling and preservation

Compared with traditional cooling methods, vacuum cooling can cool vegetables faster after harvesting. Leafy vegetables such as lettuce, lettuce, greens, and spinach are particularly suitable for this process because they have a large surface-to-volume ratio. Almost all vegetables (such as beans, strawberries, etc.) are suitable for vacuum pre-cooling and preservation. Fresh flowers (such as tulips, roses, etc.) can also be preserved by vacuum pre-cooling. The advantages of the pre-cooling preservation process: low energy consumption; short cooling time; can be cooled to the center; significantly increasing the preservation period.

Freeze-dried

Lyophilization is a dehydration process often used for the preservation or ease of transportation of perishable products. The product drying process is achieved by freezing and vacuuming the moisture in the product directly from solid ice to water vapor.

Main advantages of freeze-drying process:

Prevents the product from re-absorbing moisture and can be stored at room temperature without refrigeration

●Less damage to products than high-temperature dehydration methods

●Does not cause shrinkage of the dried product (maintains appearance)

Vacuum kneading/tumbling, vacuum chopping, vacuum filling

Vacuum Kneading/Tumbling: Kneading – makes the meat retain its shape faster and become more tender.

Roll and knead – for more flavor (more and more in demand). The tumbling machine first puts the meat in and then evacuates it, which can make the temperature of the meat more uniform and the taste better; in the second step, seasoning is added to make the marinating more even in a vacuum environment, lasting 3 to 24 hours (ham needs to be marinated for 24 hours ), which will improve taste, color, weight, shelf life, etc.

Vacuum chopping and mixing: mainly used in meat processing (such as making sausages, etc.). Vacuum chopping and mixing can form a stable and dense gel, and the volume can be reduced by 5-7% under the same weight, which can reduce packaging costs and the number of packaging boxes. It helps to maintain the essence of food, improve hygiene, reduce oxidation, and make it easier for seasonings to absorb flavor.

Vacuum filling: mainly used for meat processing. Vacuum filling is used to continuously process large pieces of meat without destroying the original form, obtaining a higher quality product without bubbles and bacteria, and improving the color uniformity and quality consistency of the product.

Vacuum stirring, vacuum cooking

Vacuum stirring: Its purpose is to eliminate the mixing of air during stirring and improve product quality (reduce the degree of fat oxidation and reduce exhaust during vacuum packaging). Vacuum processing also allows the raw material particle size to be increased and taste better.

Vacuum cooking: Vacuum cooking is to cook products that have been vacuum packed (requiring special vacuum film) at a lower temperature. This process requires a combination of a vacuum packaging machine (usually a chamber packaging machine) and a vacuum cooking machine, and some equipment manufacturers (OEMs) have developed equipment that integrates both functions. The main advantages of vacuum cooking:

●There is almost no weight loss after cooking

●Nutrition and taste remain unchanged

●Heating evenly

●The product is firm (especially the ham)

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business CHN

CHN