LeyNow vacuum pump assists mobile phone screen full lamination technology to achieve dust-free, bubble-free high-quality production

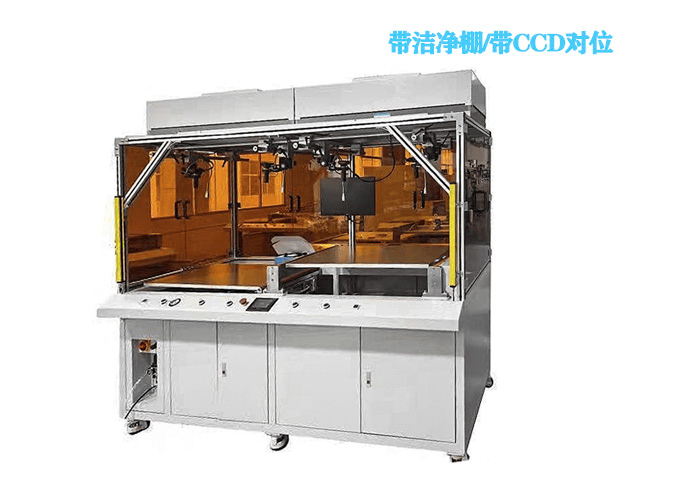

With the rapid development of technology, full lamination technology for mobile phone screens has become the mainstream of the industry. This technology effectively avoids dust intrusion by seamlessly connecting the various components of the screen, and significantly improves the display effect and touch performance. However, in the actual production process, full lamination technology also faces challenges such as yield decline and bubble generation. In order to solve these problems, many companies have invested in research and development. Among them, Helenda Technology has successfully developed high-performance laminating machines and provided effective bubble solutions by virtue of its strong technical team and rich experience accumulation.

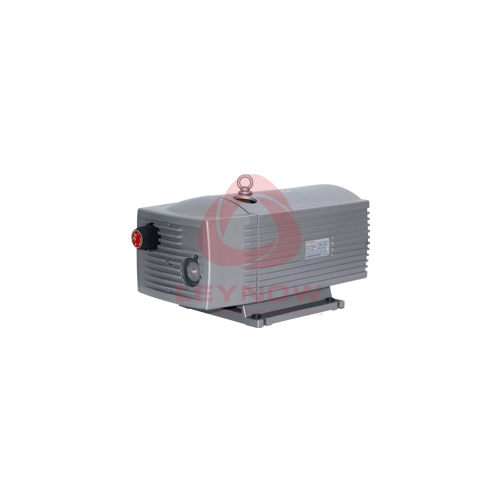

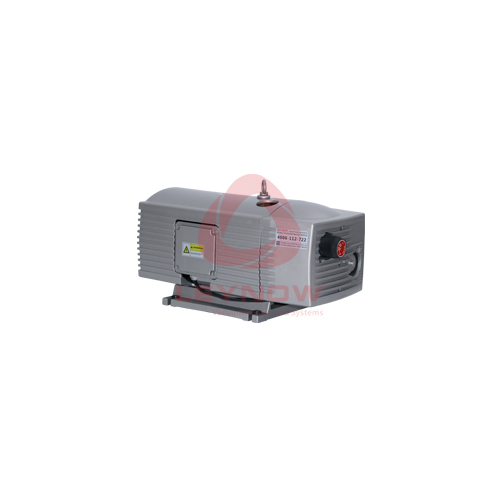

It is worth mentioning that LeyNow vacuum pumps play a key role in Helenda Technology’s laminating machines. As a professional vacuum equipment manufacturer, LeyNow provides efficient and stable vacuum power for laminating machines to ensure a perfect vacuum environment during the laminating process. This not only effectively avoids the generation of bubbles, but also greatly improves the accuracy and efficiency of fitting.

During the full lamination production process, the LCD screen first needs to be thoroughly cleaned to ensure that there are no residual glue and other contaminants. Then, a laminating machine is used for precise positioning and lamination. At this time, the LeyNow vacuum pump comes into play and quickly removes the air between the screen and the cover to form a vacuum state. In the vacuum state, the screen and cover can fit tightly to avoid the intrusion of air bubbles and dust.

After the lamination is completed, defoaming treatment is required. Helenda Technology's laminating machine is equipped with an advanced defoaming system, which can accurately control within 5 to 8 pressure ranges. At the same time, through constant temperature heating, the temperature is kept within 30 degrees to ensure the best defoaming effect. During this process, the continuous and stable operation of the LeyNow vacuum pump provided a strong guarantee for defoaming.

In addition, in terms of material selection, Helenda Technology also recommends customers to choose high-quality materials. High-quality materials not only have better fit performance, but also effectively reduce the occurrence of bubbles and adhesion. At the same time, when placing the glass cover, you also need to pay attention to avoid excessive adhesion to ensure the best bonding effect on the curved surface.

In practical applications, LeyNow vacuum pumps have won widespread praise for their low noise, low vibration and high vacuum characteristics. Its ultra-high stability and reliability provide a strong guarantee for the full-fit production of mobile phone screens. At the same time, LeyNow also provides comprehensive after-sales service and technical support to ensure that customers have no worries during use.

In general, LeyNow vacuum pumps play an important role in the full lamination technology of mobile phone screens. Through close cooperation with Helenda Technology and other companies, LeyNow continues to promote the progress and innovation of vacuum technology, providing more efficient and environmentally friendly solutions for mobile phone screen production. In the future, with the further popularization and application of full lamination technology, it is believed that LeyNow vacuum pumps will continue to play a key role in promoting the development of mobile phone screen production towards higher quality and higher efficiency.

In addition to their application in mobile phone screen production, LeyNow vacuum pumps are also widely used in other fields. For example, in medical equipment , LeyNow vacuum pumps provide stable and reliable vacuum power for suction systems; in vacuum packaging equipment, LeyNow vacuum pumps ensure the efficiency and hygiene of the packaging process. These applications fully demonstrate the excellent performance and broad application prospects of LeyNow vacuum pumps in different industries.

In addition, with the increasing awareness of environmental protection, LeyNow vacuum pumps are favored by more and more companies due to their low energy consumption and environmental protection performance. LeyNow has always been committed to developing more efficient and environmentally friendly vacuum pump products to meet the needs and challenges of different industries. This persistent pursuit of innovation and environmental protection has enabled LeyNow to maintain its leading position in the field of vacuum pumps.

Article source:https://www.leynow.com.cn/news/994.html

Disclaimer: If the article needs to be reprinted, please indicate the source. Some articles and pictures on this site come from online editors. If there are any copyright issues, please communicate and resolve them in time.

LeyNow Company is a high-tech enterprise that develops, sells vacuum pumps and provides solutions in the vacuum field. It provides users with the most reliable, safe and easy-to-use vacuum equipment products and high-quality professional services to help global customers and partners achieve success. The company's main products include: rotary vane vacuum pumps, screw vacuum pumps, Roots vacuum pumps, piston vacuum pumps, etc.

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business CHN

CHN