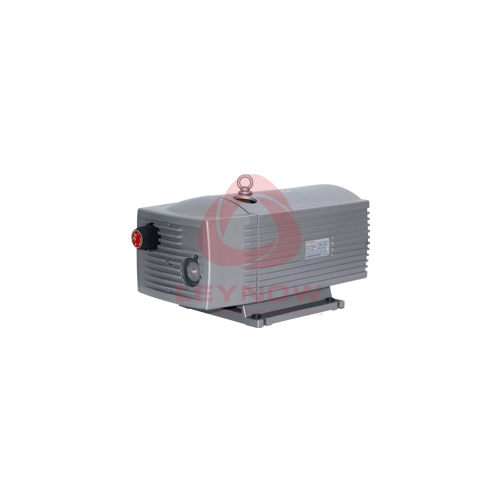

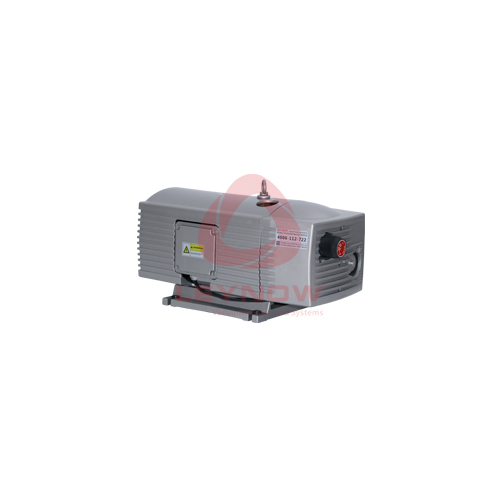

LeyNow vacuum pump leads the innovation of flap lamination technology to achieve efficient and environmentally friendly production

In today's industrial manufacturing field, continuous technological innovation is driving the dual improvement of production efficiency and environmental protection performance. Recently, a technology that combines a double-layer pore vacuum adsorption flipping platen with an advanced flipping laminating machine has attracted widespread attention. This technology not only significantly improves the efficiency and stability of lamination production, but also achieves resource saving and waste reduction through refined pore control, contributing to environmental protection.

It is worth mentioning that in this innovative technology, LeyNow vacuum pumps play a central role. As a leader in vacuum technology, LeyNow vacuum pumps, with their excellent performance and reliability, provide powerful vacuum power for the double-layer air hole vacuum adsorption flipping platen. By precisely controlling the main tracheal valve, tracheal diversion valve and cylindrical guide valve, the LeyNow vacuum pump can ensure that the opening and closing of all pores are accurately adjusted to meet the production requirements of square products of various sizes.

Specifically, this vacuum adsorption flipping table with double-layer air holes has a unique design. It includes a table main body, multiple cylindrical guide valves arranged in the X-axis direction, multiple air guide tubes arranged in the Y-axis direction, A main tracheal valve and multiple tracheal diverter valves. This design allows the platen to flexibly adjust the adsorption area according to the size and shape of the product, ensuring that the product remains stable during the lamination process.

The flip laminating machine is an advanced equipment that integrates a dispensing controller, vacuum adsorption turning platen, vacuum adsorption platform, dispensing movement mechanism, button control panel, touch screen controller, main frame and electric control box. . With the support of LeyNow vacuum pump, this laminating machine can achieve efficient and precise laminating operation, greatly improving production efficiency.

In practical applications, the operator only needs to set the parameters through the touch screen controller, and the dispensing controller and dispensing motion mechanism will accurately dispense glue according to the preset trajectory. At the same time, the vacuum adsorption turning platen and vacuum adsorption platform, driven by the LeyNow vacuum pump, can quickly reach the required vacuum degree, ensuring that the product will not shift or generate bubbles during the lamination process.

In addition, by adjusting the main tracheal valve, tracheal diversion valve and cylindrical guide valve, the operator can easily control the opening and closing status of all stomata. This flexibility allows the laminating machine to adapt to product production needs of different sizes and shapes, thereby maximizing resource utilization and minimizing waste.

It is worth mentioning that the noise and vibration generated by LeyNow vacuum pumps during operation are very low, which makes the operating environment more comfortable and pleasant. At the same time, its ultra-high vacuum degree and ultra-low power consumption also save enterprises a lot of energy costs.

In general, LeyNow vacuum pump plays a key role in the application of double-layer air hole vacuum adsorption flipping platen and flipping laminating machine. It not only improves production efficiency and product quality stability, but also achieves resource saving and environmental protection performance improvement through refined pore control and low energy consumption operation. With the further promotion and application of this technology, it is believed that LeyNow vacuum pumps will continue to lead technological innovation in the field of industrial manufacturing and make greater contributions to the sustainable development and environmental protection of enterprises.

Looking to the future, with the continuous advancement of science and technology and the increasingly diversified market demands, we expect LeyNow vacuum pumps to demonstrate their excellent performance and innovative strength in more fields. Whether in semiconductor manufacturing, medical equipment or other high-precision manufacturing fields, LeyNow vacuum pumps will provide strong support for industrial production with their excellent performance and reliability. At the same time, we also expect more companies to join the ranks of environmentally friendly production and jointly promote green and sustainable development in the industrial manufacturing field.

Article source:https://www.leynow.com.cn/news/993.html

Disclaimer: If the article needs to be reprinted, please indicate the source. Some articles and pictures on this site come from online editors. If there are any copyright issues, please communicate and resolve them in time.

LeyNow Company is a high-tech enterprise that develops, sells vacuum pumps and provides solutions in the vacuum field. It provides users with the most reliable, safe and easy-to-use vacuum equipment products and high-quality professional services to help global customers and partners achieve success. The company's main products include: rotary vane vacuum pumps, screw vacuum pumps, Roots vacuum pumps, piston vacuum pumps, etc.

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business CHN

CHN