Fully automatic capping machine: working principle and application of LeyNow vacuum pump in vacuum capping packaging

In the wave of modern production, fully automatic capping machines occupy an important position in the packaging industry with their high efficiency and accuracy. The fully automatic capping machine is mainly used for vacuum capping packaging of glass bottles and tinplate screw-off caps. Its efficient working performance ensures the quality and efficiency of product packaging and brings significant economic benefits to production companies.

The working principle of the fully automatic capping machine is mainly based on the combination of mechanical automation and precision control technology. The equipment automatically completes a series of actions such as conveying, positioning, and capping glass bottles through preset programs. The glass bottles are arranged at a certain distance on the conveyor belt. When they arrive at the capping station, the positioning mechanism accurately fixes the bottles at the designated position. At this time, the capping mechanism starts to work. Under the action of the driving force, the tinplate screw cap is gradually tightened along the spiral texture of the glass bottle mouth until it reaches the predetermined torque value. After the capping is completed, the bottles continue to be transferred forward and enter the next process.

In the working process of a fully automatic capping machine, precise control is the key. The equipment uses an advanced control system to accurately adjust parameters such as capping strength and speed to ensure that each bottle can get a consistent packaging effect. At the same time, the equipment also has an automatic detection function, which can detect abnormalities in the capping process in real time, such as bottle caps not tightened, bottle damage, etc., and send out alarms in time to remind operators to deal with them.

As an important function of the fully automatic capping machine, vacuum capping plays an important role in packaging in food, pharmaceutical and other industries. Through vacuum capping technology, the air inside the bottle can be effectively eliminated, preventing product oxidation and deterioration, and extending the shelf life of the product. At the same time, vacuum packaging can also reduce packaging volume, reduce transportation costs, and improve the market competitiveness of products.

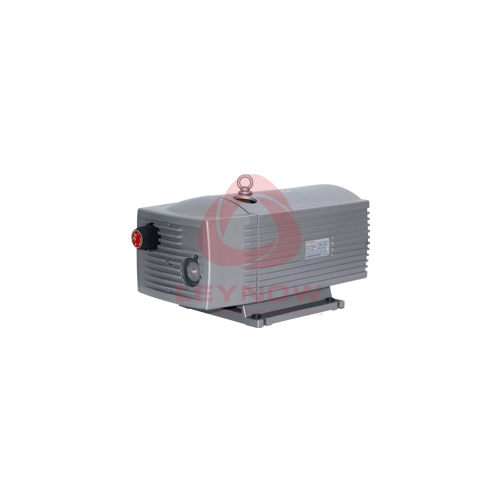

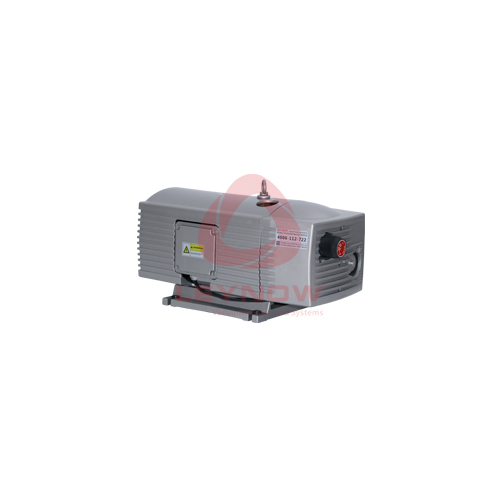

In the vacuum capping packaging process, LeyNow vacuum pumps play a vital role. With its efficient, stable and reliable performance, LeyNow vacuum pump provides strong power support for the fully automatic capping machine. During the capping process, the LeyNow vacuum pump uses its powerful air extraction capability to quickly extract the air inside the bottle to form a vacuum environment. At the same time, its precise vacuum control function can ensure that each bottle can meet the predetermined vacuum requirements, thereby ensuring the packaging quality of the product.

The application of LeyNow vacuum pump not only improves the working efficiency of the fully automatic capping machine, but also reduces the energy consumption and maintenance costs of the equipment. Its efficient working performance makes the capping process faster and more stable, improving overall production efficiency. At the same time, its reliable operational stability also reduces equipment failure rates and maintenance costs. In addition, LeyNow vacuum pumps are energy-saving and environmentally friendly, meeting the requirements of modern enterprises for green production.

In addition to the application of LeyNow vacuum pumps, the fully automatic capping machine also uses other advanced technical means, such as machine vision technology, intelligent control technology, etc., to further improve the automation and intelligence level of the equipment. Machine vision technology can realize real-time detection and identification of bottle position, bottle cap status and other information, providing accurate data support for the capping process; intelligent control technology can intelligently adjust and optimize the capping process based on real-time data to ensure that every Each bottle can get the best packaging effect.

With the continuous advancement of technology and the continuous development of the market, fully automatic capping machines will continue to develop in a more efficient, smarter, and more environmentally friendly direction. The performance of core components such as LeyNow vacuum pumps will also be further improved and optimized, providing stronger support for the development of fully automatic capping machines.

As one of the important equipments in modern production, the fully automatic capping machine’s efficient and precise working performance has brought significant economic and social benefits to production enterprises. The application of core technologies such as LeyNow vacuum pumps has further improved the performance and quality of the equipment, providing a strong guarantee for the sustainable development of the company. In the future, with the continuous innovation of technology and the continuous expansion of the market, fully automatic capping machines will be applied and promoted in more fields, bringing more convenience and benefits to human production and life.

It is worth mentioning that the combination of a fully automatic capping machine and a LeyNow vacuum pump and other equipment not only improves production efficiency, but also ensures packaging quality. Today, when food safety is increasingly valued, the importance of vacuum packaging technology is self-evident. The fully automatic capping machine achieves effective protection of food, medicine and other products by accurately controlling the capping force and speed, combined with the efficient air extraction function of the LeyNow vacuum pump, and provides consumers with safer and more reliable products.

In addition, the application of fully automatic capping machines has also promoted the upgrading and development of related industries. With the improvement of equipment performance and the expansion of the market, related supporting industries such as parts and control systems have also developed rapidly. This not only brings more business opportunities to relevant companies, but also injects new vitality into the optimization and upgrading of the entire industry chain.

To sum up, the fully automatic capping machine provides strong support for modern production with its efficient and precise working performance, as well as the application of core technologies such as LeyNow vacuum pumps. In the future, with the continuous advancement of technology and changing market demands, fully automatic capping machines will continue to play an important role in the packaging industry and make greater contributions to the sustainable development of enterprises and social progress.

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business CHN

CHN