Revealing the secrets of vacuum pump packaging machines : how technology protects food freshness

In today's era of emphasis on food safety and freshness, vacuum pump packaging machines have become a powerful assistant in the food industry. How does this efficient and intelligent machine ensure the freshness and safety of food by relying on the exquisite cooperation of vacuum pumps and controllers? Below, let’s find out.

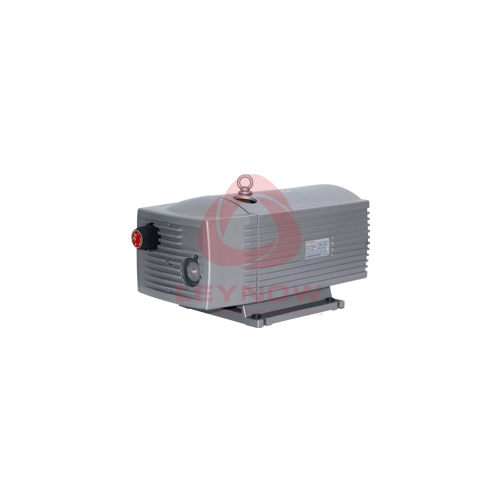

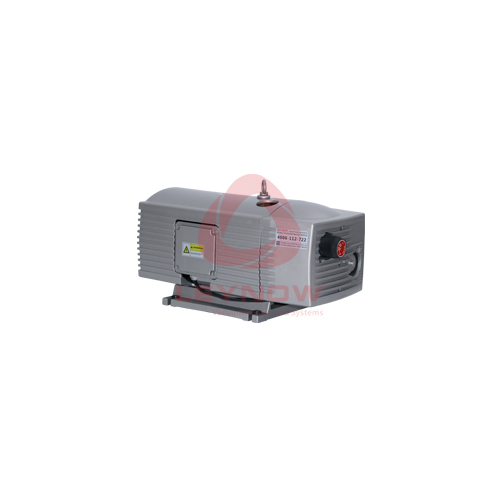

The working principle of the vacuum pump packaging machine can be described as the embodiment of the perfect combination of technology and life. Its core component, the vacuum pump, is responsible for extracting oxygen from plastic bags. The controller, like a brain, accurately controls the working procedures of the entire vacuum packaging machine.

During the specific operation, the staff will first put the items that need to be packed into specially designed plastic bags. This plastic bag is specially treated to withstand the strong suction generated by the vacuum pump without breaking. Next, the bag is placed flat on the sealer in the vacuum chamber, ready for the next step.

As the controller issues instructions, the vacuum pump starts running. Its powerful suction force quickly acts on the plastic bag and begins to suck out the oxygen in the bag. This step is crucial because the presence of oxygen is one of the main culprits in food spoilage. By extracting oxygen, the vacuum pump creates a low-oxygen or even oxygen-free environment for food, greatly extending the shelf life of food.

While the vacuum pump is working, the sealer is also working nervously. Once the oxygen in the bag is extracted to a certain extent, the sealer will immediately start to seal the mouth of the plastic bag tightly. The time control of this step is very critical, and sealing must be completed quickly when the oxygen is extracted to the optimal ratio to ensure the packaging effect.

After sealing is completed, the entire packaging process comes to an end. The vacuum pump stops working, the packaging bag is taken out of the vacuum chamber, and a perfect vacuum packaging is completed. Throughout the process, the precise control of the controller and the efficient work of the vacuum pump are inseparable, jointly ensuring the quality and efficiency of packaging.

It is worth mentioning that different types of vacuum pump packaging machines may have differences in working principles and efficiency. For example, machines using relays + vacuum generators are relatively simple, low-cost, and suitable for small businesses or homes; while high-end models using PLC control + LCD display + high-quality vacuum pumps are more intelligent, easy to operate, and highly visual High, suitable for large enterprises or occasions that have higher requirements for product quality.

In addition to the working principle, the maintenance and upkeep of the vacuum pump packaging machine is equally important. For example, the suction valve O-ring falling off is a common fault. When dealing with this problem, the staff needs to unplug the vacuum tube on the pump nozzle, remove the suction nozzle, and take out the compression spring and suction valve. Then gently stretch the O-ring a few times, re-insert it into the groove, and then install it in the reverse order. In addition, the wear of the rotary vane in the vacuum pump is also a problem that needs attention. Once the rotary vane is found to be severely worn, it should be replaced with a new one immediately to ensure the normal operation of the vacuum pump.

With the continuous development of technology, vacuum pump packaging machines are also constantly upgraded and improved. In the future, we have reason to believe that this efficient and intelligent packaging equipment will play a greater role in the food industry and provide a stronger guarantee for people's food safety and freshness.

Article source:https://www.leynow.com.cn/news/984.html

Disclaimer: If the article needs to be reprinted, please indicate the source. Some articles and pictures on this site come from online editors. If there are any copyright issues, please communicate and resolve them in time.

LeyNow Company is a high-tech enterprise that develops, sells vacuum pumps and provides solutions in the vacuum field. It provides users with the most reliable, safe and easy-to-use vacuum equipment products and high-quality professional services to help global customers and partners achieve success. The company's main products include: rotary vane vacuum pumps, screw vacuum pumps, Roots vacuum pumps, piston vacuum pumps, etc.

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business CHN

CHN