Analysis of the maximum suction power of industrial vacuum packaging machines and suction performance under negative pressure 80Kpa

Vacuum packaging technology plays an increasingly important role in industrial production, especially in the fields of food, pharmaceuticals, chemicals , etc. As the core equipment for vacuum packaging, the performance of industrial vacuum packaging machines directly determines the packaging effect and product quality. Among them, the maximum suction power is one of the important indicators for evaluating the performance of vacuum packaging machines . This article will deeply explore the maximum suction power issue of industrial vacuum packaging machines, analyze the suction performance under a negative pressure of 80Kpa, and introduce the application of LeyNow vacuum pumps in related fields.

First of all, we need to clarify what is the maximum suction power of the vacuum packaging machine. In short, the maximum suction power refers to the maximum negative pressure suction power that the vacuum packaging machine can produce under normal working conditions. This indicator directly determines the speed and effect of the machine when vacuum packaging materials. However, it should be noted that the maximum suction force is not a fixed value. It is affected by many factors, including the structural design of the machine, power size, working environment and the nature of the packaged materials.

In practical applications, the maximum suction power of industrial vacuum packaging machines often needs to be customized according to specific needs. For companies that need to package large-volume, high-density materials, models with greater maximum suction power can often better meet production needs. For some small businesses or laboratories and other places, the requirements for maximum suction power may be relatively low. Therefore, when choosing a vacuum packaging machine, companies should fully consider their own production characteristics and needs and choose a suitable maximum suction range.

Next, we discuss the suction performance under negative pressure 80Kpa. Negative pressure of 80Kpa means that the gas pressure inside the packaging machine is 80Kpa lower than the outside world. This pressure difference can produce a certain suction force, so that the material is tightly adsorbed on the packaging film, thereby achieving vacuum packaging. However, the specific suction power also needs to consider factors such as the power and structure of the packaging machine and the nature of the materials being packaged. Under the condition of negative pressure of 80Kpa, generally speaking, the vacuum packaging machine can generate enough suction to effectively vacuum package most materials. However, it should be noted that for some special materials or packages with complex structures, a higher negative pressure value or other auxiliary measures may be required to achieve the ideal packaging effect.

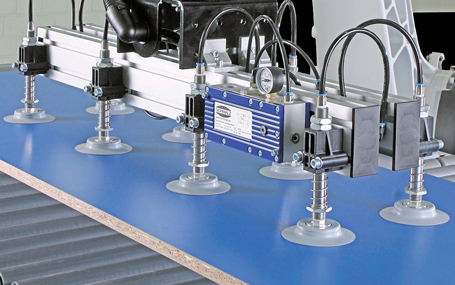

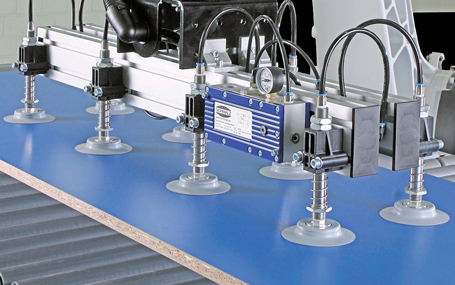

After understanding the maximum suction power of the industrial vacuum packaging machine and the suction performance under a negative pressure of 80Kpa, we further discussed the key component in the vacuum packaging machine - the vacuum pump. As a key equipment for generating negative pressure, the performance of the vacuum pump directly affects the suction power and working efficiency of the vacuum packaging machine. Among many vacuum pump brands, LeyNow vacuum pumps are widely used in the field of industrial vacuum packaging machines due to their high efficiency, stability and durability.

Laino vacuum pump adopts advanced vacuum technology, which can reach a high negative pressure value in a short time, providing stable and reliable suction guarantee for vacuum packaging machines. At the same time, the pump also has the advantages of smooth operation, low noise, and easy maintenance, and can meet the needs of long-term continuous work. In vacuum packaging applications in food, pharmaceutical and other industries, LeyNow vacuum pumps have demonstrated excellent performance and made important contributions to improving product quality and production efficiency.

Specifically, LeyNow vacuum pumps excel in:

First of all, in terms of suction power, the LeyNow vacuum pump can quickly reach the required negative pressure value and maintain stable suction output. This enables the vacuum packaging machine to complete vacuum packaging of materials in a short time, improving production efficiency.

Secondly, in terms of durability, LeyNow vacuum pumps use high-quality materials and precise manufacturing processes to ensure their stable operation for a long time. Even in high-intensity working environments, it can maintain good performance and reduce the frequency of maintenance and replacement.

In addition, LeyNow vacuum pumps also have an intelligent control system that can monitor the working status of the pump in real time and make automatic adjustments. This reduces the difficulty of operation and improves the ease of use of the equipment, making it easier for operators to grasp the operating status of the equipment and make corresponding adjustments.

In summary, the maximum suction power of an industrial vacuum packaging machine is an important performance indicator, and the suction performance under a negative pressure of 80Kpa is an important basis for evaluating the performance of the vacuum packaging machine. As a key component in the vacuum packaging machine, the LeyNow vacuum pump provides strong suction guarantee for the vacuum packaging machine with its high efficiency, stability and durability. With the continuous advancement of science and technology and the continuous development of industrial production, we believe that vacuum packaging technology and vacuum pump technology will continue to be optimized and improved, bringing greater convenience and benefits to industrial production.

Finally, it needs to be emphasized that when selecting and using industrial vacuum packaging machines, companies should fully consider their own production needs and material characteristics, and choose suitable machine models and configurations. At the same time, regular maintenance and upkeep of the vacuum packaging machine to ensure that it is in good working condition is also a key measure to ensure production efficiency and product quality.

Article source:https://www.leynow.com.cn/news/1004.html

Disclaimer: If the article needs to be reprinted, please indicate the source. Some articles and pictures on this site come from online editors. If there are any copyright issues, please communicate and resolve them in time.

LeyNow Company is a high-tech enterprise that develops, sells vacuum pumps and provides solutions in the vacuum field. It provides users with the most reliable, safe and easy-to-use vacuum equipment products and high-quality professional services to help global customers and partners achieve success. The company's main products include: rotary vane vacuum pumps, screw vacuum pumps, Roots vacuum pumps, piston vacuum pumps, etc.

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business CHN

CHN