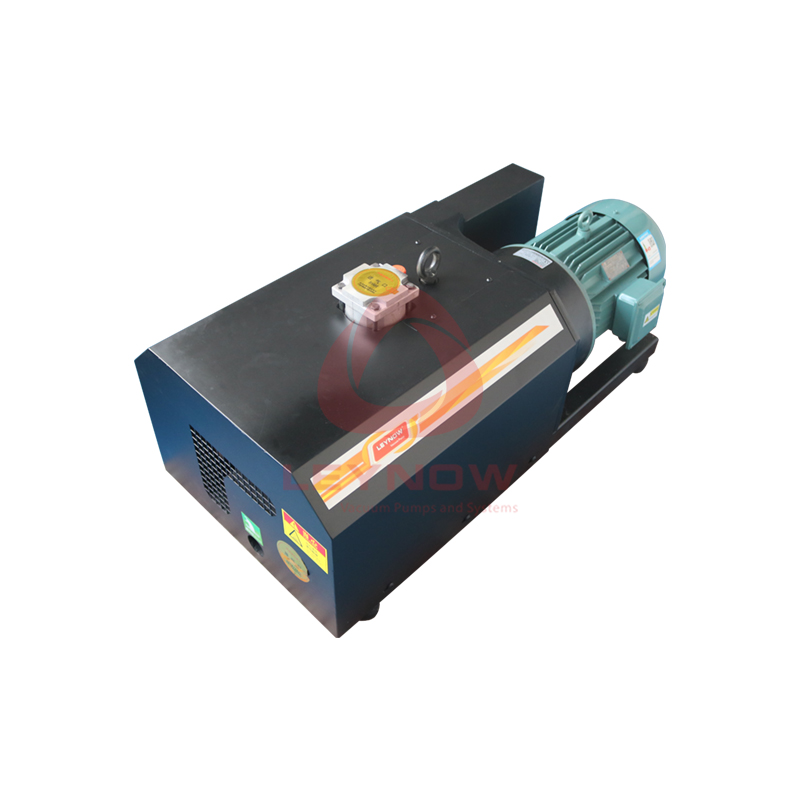

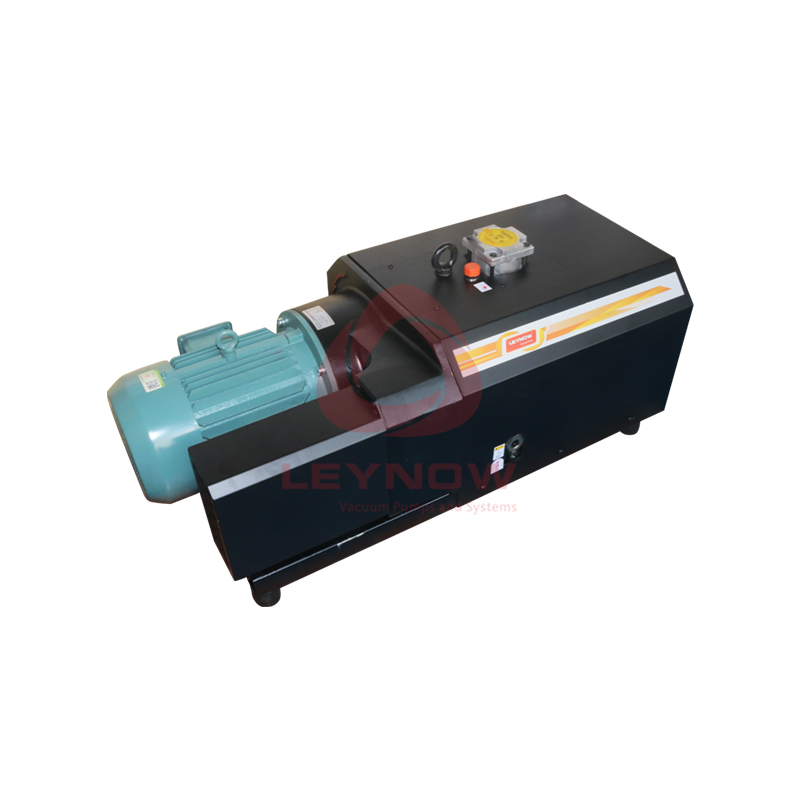

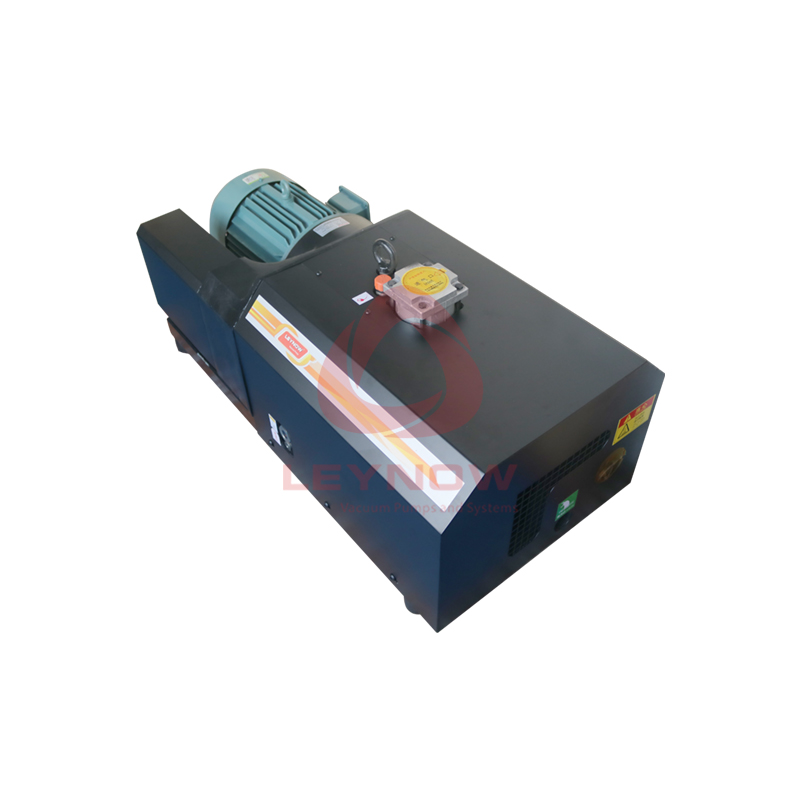

Revealing the secrets of vacuum pumps: Applications and unique structures of claw-type dry vacuum pumps that you don’t know

Today, with the rapid development of science and technology, vacuum pumps, as an important industrial equipment, have been widely used in various fields. Among them, claw-type dry vacuum pumps are gradually gaining favor in the industry due to their unique working principles and structures. This article will deeply explore the working principle, structural characteristics and application of claw-type dry vacuum pumps in various fields, and unveil the veil of this mysterious device for readers.

Claw dry vacuum pump, as the name suggests, is a dry vacuum pump that uses a claw rotor for air extraction. It uses gap-free and frictionless engagement between pairs of claw-type rotors connected on two shafts, between the rotor and the inner wall of the pump chamber, and between the rotor and the partition to form changes in the volume of the closed cavity to complete the suction. exhaust process. This unique working principle allows the claw dry vacuum pump to eliminate the need for lubricating oil during the pumping process, thereby avoiding oil pollution and oil vapor emissions, and achieving the dual goals of environmental protection and energy saving.

In terms of structure, claw dry vacuum pumps generally adopt a multi-stage rotor series design. This design not only improves the pumping efficiency of the pump, but also makes the pump more stable and reliable during operation. The multi-stage rotor series structure enables the claw dry vacuum pump to perform well in working environments with high pressure differences and high vacuum degrees, meeting the needs of various complex working conditions.

So, in which fields are claw dry vacuum pumps widely used? First of all, in the metallurgical industry, claw-type dry vacuum pumps are widely used in vacuum smelting, vacuum smelting and other processes. Its efficient and stable performance provides reliable technical support for metallurgical enterprises and improves production efficiency.

Secondly, in the chemical industry, claw dry vacuum pumps also play an important role. In the chemical production process, many processes need to be carried out in a vacuum environment, such as vacuum drying, vacuum distillation, etc. Claw-type dry vacuum pumps provide ideal vacuum solutions for chemical companies with their high efficiency and environmental protection.

In addition, in the food industry, claw-type dry vacuum pumps are also widely used in vacuum packaging, vacuum freezing and other processes. By removing air from food packaging, the shelf life of food is extended and the quality of food is improved. At the same time, the oil-free design of the claw dry vacuum pump also avoids the potential threat of oil contamination to food safety.

In the electronic coating industry, claw-type dry vacuum pumps also play an important role. In the manufacturing process of electronic products, vacuum coating technology is widely used to improve the performance and appearance of products. The efficient pumping capacity of the claw-type dry vacuum pump provides a stable vacuum environment for the electronic coating process and ensures the stability of product quality.

It is worth mentioning that claw-type dry vacuum pumps are also widely used in the field of scientific research. In the laboratory, many scientific experiments need to be carried out in a vacuum environment, such as material preparation, physical experiments, etc. The claw-type dry vacuum pump provides ideal experimental conditions for scientific researchers with its high precision and high reliability.

To sum up, claw-type dry vacuum pumps are widely used in various fields due to their unique working principles and structural characteristics. It not only improves production efficiency and reduces energy consumption, but also brings significant environmental benefits to enterprises. With the continuous advancement of science and technology and the in-depth expansion of applications, claw dry vacuum pumps will play a more important role in the future, providing strong support for the development of various industries.

However, we should also see that claw dry vacuum pumps still face some challenges during application. For example, the performance of a claw dry vacuum pump may be affected in harsh environments such as high temperature and high humidity. Therefore, how to further improve the adaptability and stability of claw dry vacuum pumps will be the focus of future research and development.

In addition, with the rapid development of new energy, new materials and other fields, the performance requirements for vacuum pumps are becoming higher and higher. As an efficient and environmentally friendly vacuum equipment, the claw dry vacuum pump is expected to play a greater role in these fields. At the same time, we also need to pay attention to the research and development and application of new vacuum pump technology to meet the diverse needs of different industries for vacuum technology.

In short, as an important industrial equipment, the claw dry vacuum pump has broad application prospects in various fields. We should strengthen the research and innovation of claw dry vacuum pump technology, promote its application and development in more fields, and make greater contributions to promoting the transformation, upgrading and sustainable development of my country's industry.

In future developments, we look forward to seeing more technological breakthroughs and application innovations regarding claw dry vacuum pumps. Whether it is to improve the pumping efficiency, reduce energy consumption, expand application fields, and improve equipment stability, we need to work together to continuously promote the advancement and development of claw dry vacuum pump technology.

At the same time, we should also pay attention to the overall development trend of the vacuum pump industry. With the continuous improvement of global environmental awareness and the gradual implementation of energy conservation and emission reduction policies, oil-free, low energy consumption, and high-efficiency vacuum pumps will become the mainstream of the market. Therefore, strengthening the research and development and promotion of environmentally friendly vacuum pumps such as claw dry vacuum pumps will help promote the green and sustainable development of the entire industry.

In short, as an efficient and environmentally friendly vacuum equipment, the claw dry vacuum pump has wide applications and huge development potential in various fields. We should fully realize its importance, strengthen technological research and development and application innovation, and make greater contributions to promoting the progress and development of our country's industry.

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business CHN

CHN