Discussion on the application of automatic dispensing machines in the chip packaging industry and solutions to glue bubbles and vacuum pump suction requirements

With the rapid development of modern electronic technology, the chip is its core component, and the quality of its packaging technology is directly related to the performance and stability of the product. As an important equipment in the chip packaging industry, automatic dispensing machines are increasingly used in chip bonding, primer filling, surface coating, etc. This article will discuss in detail the application of automatic dispensing machines in the chip packaging industry, propose solutions to the problem of glue bubbles, and discuss the suction requirements of vacuum pumps.

1. Application of automatic dispensing machines in chip packaging industry

Automatic dispensing machines play a pivotal role in the chip packaging industry due to their high precision and high efficiency. During the chip bonding process, the automatic glue dispensing machine can accurately control the amount and position of glue application to ensure a strong bond between the chip and the substrate. In the base material filling process, the automatic dispensing machine can achieve a uniform, bubble-free filling effect and improve the stability and reliability of the chip. In addition, in terms of surface coating, automatic dispensing machines can accurately control the thickness and uniformity of the coating, improving the appearance quality and protective performance of the chip.

Applying automatic dispensing machines to the chip packaging industry can not only improve production efficiency and reduce labor costs, but also significantly improve packaging quality. By optimizing dispensing parameters and process flow, more accurate and efficient chip packaging can be achieved, providing strong support for the development of the electronics industry.

2. Solution to bubbles in glue

During the chip packaging process, glue bubbles are a common problem. The existence of bubbles will seriously affect the quality and stability of the packaging, so effective measures must be taken to solve it.

First of all, we can start with the selection and use of glue. Choosing glue with low viscosity and easy defoaming can effectively reduce the generation of bubbles. At the same time, during use, ensure that the glue is stirred evenly to avoid the generation of bubbles due to uneven internal components of the glue.

Secondly, we can reduce bubbles by adjusting the parameters of the automatic dispensing machine. For example, appropriately increasing the dispensing pressure allows the glue to more fully fill the gap between the chip and the substrate, thereby squeezing out air bubbles. In addition, the dispensing speed and amount can be adjusted to make the glue more uniform during the coating process and reduce the generation of bubbles.

Finally, the introduction of vacuum degassing technology is also an effective solution. Before the glue is applied, the air bubbles in the glue are extracted through a vacuum pump, which can greatly reduce the air bubble content. This technology can solve the problem of glue bubbles to a certain extent and improve the packaging quality.

3. Suction requirements of vacuum pump

In the process of solving the problem of glue bubbles, the suction power of the vacuum pump is a key factor. The suction power of the vacuum pump directly affects the extraction effect of bubbles. Therefore, when selecting a vacuum pump, we need to determine the appropriate suction power requirements based on specific application needs and glue characteristics.

Generally speaking, for the chip packaging industry, the suction power of the vacuum pump needs to be strong enough to ensure that the bubbles in the glue can be effectively extracted. At the same time, the stability of the vacuum pump is also very important, and it needs to be able to work continuously for a long time without failure. In addition, the vacuum pump also needs to have high accuracy and reliability to ensure that the glue will not be contaminated or damaged during the pumping process.

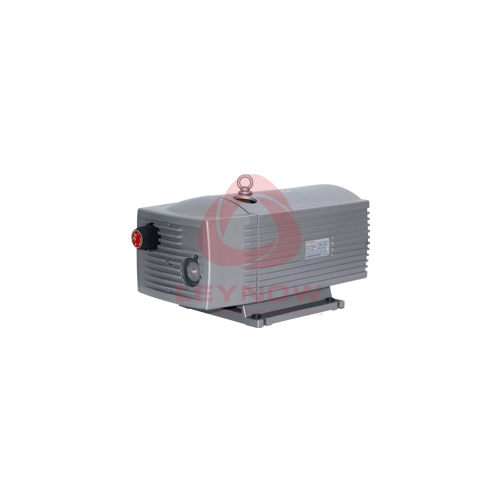

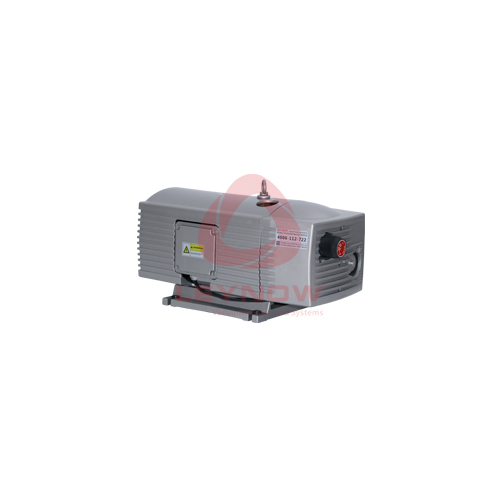

As a high-performance vacuum equipment , LeyNow vacuum pump has a wide range of applications in the chip packaging industry. It is manufactured using advanced technology and high-quality materials, with powerful suction, stable performance and high-precision control capabilities. Using LeyNow vacuum pumps for glue degassing can greatly improve the quality and efficiency of packaging and reduce production costs.

In practical applications, we need to select the appropriate LeyNow vacuum pump model and parameters based on specific glue characteristics and packaging requirements. By adjusting parameters such as the suction power and working time of the vacuum pump, precise control of the glue degassing process can be achieved to achieve the best packaging effect.

4. Conclusion

The application of automatic dispensing machines in the chip packaging industry provides us with efficient and accurate packaging solutions. By optimizing dispensing parameters and introducing vacuum deaeration technology, we can effectively solve the problem of glue bubbles and improve the quality and stability of packaging. At the same time, selecting a suitable vacuum pump and setting its suction requirements reasonably are the keys to achieving efficient deaeration.

Applying this method to daily work can not only improve our work efficiency, but also bring greater impetus to the development of the chip packaging industry. With the continuous advancement of technology and the continuous expansion of application fields, we believe that automatic dispensing machines and vacuum pumps will play a more important role in the future, injecting new vitality into the development of the electronics industry.

In summary, the application of automatic glue dispensing machines in the chip packaging industry, its solutions to glue bubbles and vacuum pump suction requirements are a topic worthy of in-depth study and discussion. By continuously optimizing technical processes and equipment performance, we can bring more efficient and accurate solutions to the chip packaging industry and promote the sustainable development and innovation progress of the entire industry.

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business CHN

CHN