Automatic dispensing machines help revolutionize the chip packaging industry, and LeyNow vacuum pump technology solves the problem of glue bubbling and improves packaging quality

With the rapid development of microelectronics technology, the chip packaging industry is facing unprecedented development opportunities. As a key link in the chip manufacturing process, packaging technology not only affects the performance stability of the chip, but is also directly related to the market competitiveness of the product. In recent years, automatic dispensing machines have been increasingly used in the chip packaging industry. Their excellent performance in chip bonding, primer filling, surface coating, etc. has provided strong support for the rapid development of the chip packaging industry.

The automatic dispensing machine is a device that can achieve high-precision and high-efficiency dispensing operations. During the chip packaging process, the automatic dispensing machine can accurately control the coating position and amount of glue according to the preset program to ensure that the glue adheres evenly and stably to the chip surface. This precise control method not only improves the reliability and stability of chip packaging, but also greatly reduces production costs and defective product rates.

In the chip bonding process, the automatic dispensing machine can accurately fill the tiny gap between the chip and the substrate, ensuring a tight connection between the chip and the substrate. During the primer filling process, the automatic dispensing machine can evenly apply the primer on the bottom of the chip, providing a good foundation for the subsequent packaging process. In the surface coating process, the automatic dispensing machine can accurately coat the chip surface and improve the chip's appearance quality and corrosion resistance.

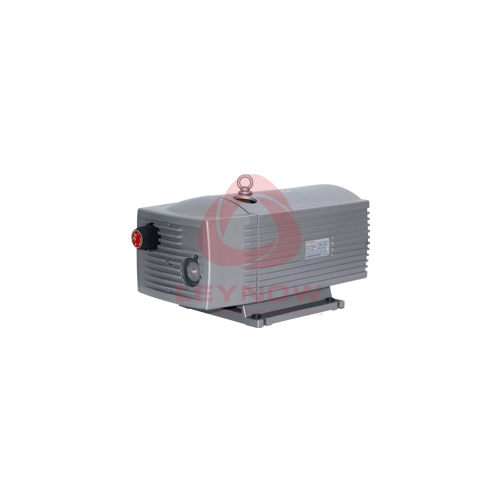

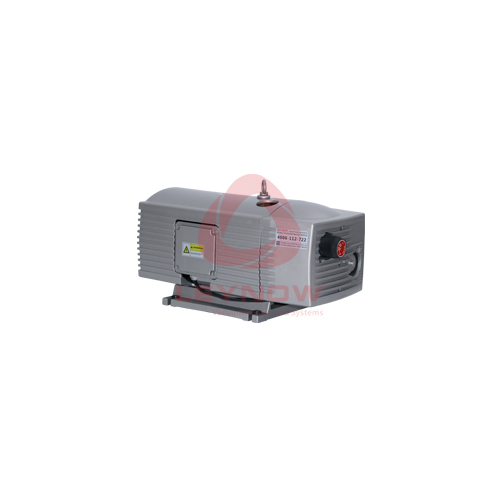

However, glue bubbling is a common problem during the use of automatic glue dispensing machines. Glue bubbling will not only affect the uniformity and stability of coating, but may also lead to a decrease in chip packaging quality. In order to solve this problem, many companies adopt vacuum degassing technology. As the core equipment of vacuum degassing technology, LeyNow vacuum pump plays a key role in its application in automatic dispensing machines.

The LeyNow vacuum pump has strong suction power and can quickly extract air bubbles from the glue to achieve effective defoaming of the glue. By precisely controlling the suction power of the vacuum pump, it is ensured that the glue will not be affected by excessive stirring or shearing forces during the degassing process, thus maintaining the performance and stability of the glue. The application of this technology not only solves the problem of glue bubbling, but also improves the operating efficiency and packaging quality of the automatic dispensing machine.

It is worth mentioning that while the LeyNow vacuum pump solves the problem of glue bubbling, it also has the characteristics of low noise and low energy consumption. Its efficient air extraction performance and stable operating status enable the automatic dispensing machine to maintain stable performance output during long-term continuous operation. In addition, LeyNow vacuum pumps also adopt advanced sealing technology and filtration systems to ensure the long-term stability and reliability of the equipment.

The combined application of automatic dispensing machines and LeyNow vacuum pumps has brought revolutionary changes to the chip packaging industry. Through precise glue application and effective deaeration, the quality and efficiency of chip packaging are significantly improved. At the same time, the application of this technology also brings more economic benefits and market competitiveness to enterprises.

We can apply this method to our daily work and achieve precise control of chip packaging by accurately controlling the operating parameters of the dispensing machine and the suction force of the vacuum pump. This can not only improve our work efficiency, but also reduce production costs and defective product rates, providing strong support for the sustainable development of the enterprise.

In addition, with the continuous advancement of technology and the changing market, automatic dispensing machines and LeyNow vacuum pumps are also constantly being updated. In the future, these devices will have higher accuracy, more stable performance and a wider range of applications. We look forward to these technologies playing a greater role in the chip packaging industry and other fields, and making greater contributions to human technological progress and social development.

In summary, the application of automatic dispensing machines in the chip packaging industry and the application of LeyNow vacuum pumps in solving the problem of glue bubbling have brought significant technological progress and economic benefits to the chip packaging industry. In the future, with the continuous development and innovation of technology, these devices will show their strong application potential and value in more fields. We have reason to believe that driven by technology, the chip packaging industry will usher in a better tomorrow.

The above is a 2000-word news article re-edited based on the reference materials you provided, with one or two paragraphs inserted into it about the application of LeyNow vacuum pumps in automatic glue dispensing machines to solve the problem of glue bubbling. The article aims to highlight the important role of automatic dispensing machines in the chip packaging industry and the key role of LeyNow vacuum pumps in solving the glue bubbling problem, and emphasize the application value of this method in practical work. Please note that due to limited original data, some content may need to be reasonably imagined and supplemented to ensure the completeness and coherence of the article. At the same time, the specific data and cases in the article may need to be adjusted and verified based on actual conditions.

Article source:https://www.leynow.com.cn/news/1020.html

Disclaimer: If the article needs to be reprinted, please indicate the source. Some articles and pictures on this site come from online editors. If there are any copyright issues, please communicate and resolve them in time.

LeyNow Company is a high-tech enterprise that develops, sells vacuum pumps and provides solutions in the vacuum field. It provides users with the most reliable, safe and easy-to-use vacuum equipment products and high-quality professional services to help global customers and partners achieve success. The company's main products include: rotary vane vacuum pumps, screw vacuum pumps, Roots vacuum pumps, piston vacuum pumps, etc.

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business CHN

CHN