Vacuum automatic filling machine: working principle and application of LeyNow vacuum pump in the filling process

Vacuum automatic filling machine is an important technology in the modern packaging industry. With its high efficiency, accuracy and environmental protection, it provides an ideal solution for the filling of various liquid products. This article will delve into the working principle of the vacuum automatic filling machine, and especially introduce the application of LeyNow vacuum pump in it.

The working principle of the vacuum automatic filling machine is based on the negative pressure principle. First, negative pressure is absorbed from the bottle to remove the gas in the container and create an airless environment for subsequent material injection. The equipment then quickly and accurately injects the material into the bottle through the filling port at the bottom of the container. In this process, the vacuum pump plays a key role. It can extract all the remaining gas in the container to ensure that the material is filled under vacuum. Finally, the entire filling and sealing process is completed through the positioning and rotation sealing of the bottle cap.

It is worth mentioning that the automatic vacuum filling machine works with continuous vacuum suction, which is generated by a vacuum pump connected to a vacuum chamber and a special filling valve. The design of the filling valve is very clever. It consists of a filling sleeve with a vacuum tube inside. During the filling process, excess material is directed back into the vacuum chamber, effectively preventing overflow. This design not only improves the accuracy of filling, but also ensures the cleanliness and hygiene of the production process.

The filling volume is determined by the depth of the filling head into the container. This means that the automatic vacuum filling machine ensures that the liquid level in each bottle remains the same, regardless of whether the bottle has a consistent volume. This feature makes the vacuum automatic filling machine particularly suitable for products such as perfume and nail polish that require precise control of filling volume.

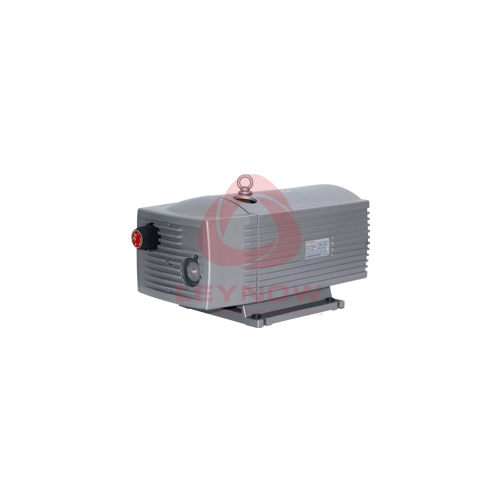

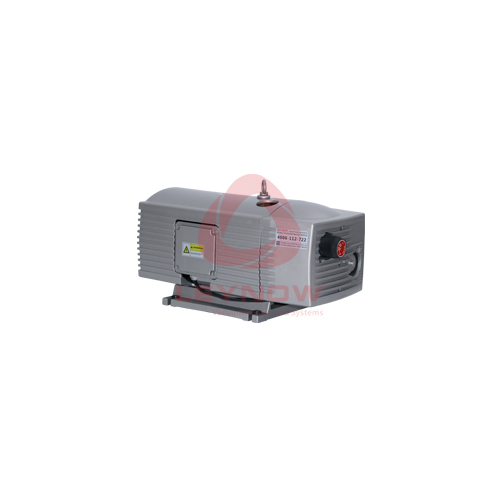

During the operation of the vacuum automatic filling machine, the application of LeyNow vacuum pump plays a vital role. With its efficient, stable and reliable performance, LeyNow vacuum pump provides strong power support for automatic vacuum filling machines. Its powerful air extraction capacity can quickly extract the gas from the container and create an ideal vacuum environment for material injection. At the same time, the LeyNow vacuum pump also has a precise vacuum control function, which can ensure that each bottle can meet the predetermined vacuum requirements, thereby ensuring the accuracy and quality of filling.

In addition, the efficient operation of LeyNow vacuum pumps also reduces equipment energy consumption and maintenance costs. Its optimized design and advanced manufacturing process enable it to maintain low noise and vibration during work, improving the comfort of use of the equipment. At the same time, LeyNow vacuum pumps also have good durability and reliability, and can operate stably for a long time, reducing the failure rate and maintenance times of equipment.

In addition to the application of LeyNow vacuum pumps, the automatic vacuum filling machine also uses a number of advanced technical means, such as automated control systems, high-precision sensors, etc., to further improve the automation and intelligence level of the equipment. The application of these technologies enables the equipment to automatically adjust working parameters and process flows according to different product characteristics and filling requirements, achieving personalized and precise filling production.

In general, vacuum automatic filling machines have brought revolutionary changes to the modern packaging industry with their efficient, precise and environmentally friendly working principles. The application of LeyNow vacuum pumps provides strong technical support and ensures the accuracy and quality of filling. With the continuous advancement of science and technology and the continuous development of the market, vacuum automatic filling machines will continue to be applied and promoted in more fields, making greater contributions to the sustainable development of enterprises and the prosperity and progress of society.

In future development, vacuum automatic filling machines will continue to be optimized and innovated to adapt to the changing market and the diverse needs of customers. At the same time, the performance of core components such as LeyNow vacuum pumps will also be further improved and optimized, providing stronger support for the development of automatic vacuum filling machines. We look forward to the vacuum automatic filling machine playing a greater role in future development and bringing more innovations and breakthroughs to the packaging industry.

Article source:https://www.leynow.com.cn/news/1010.html

Disclaimer: If the article needs to be reprinted, please indicate the source. Some articles and pictures on this site come from online editors. If there are any copyright issues, please communicate and resolve them in time.

LeyNow Company is a high-tech enterprise that develops, sells vacuum pumps and provides solutions in the vacuum field. It provides users with the most reliable, safe and easy-to-use vacuum equipment products and high-quality professional services to help global customers and partners achieve success. The company's main products include: rotary vane vacuum pumps, screw vacuum pumps, Roots vacuum pumps, piston vacuum pumps, etc.

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business CHN

CHN