Glass bottle vacuum capping machine: key technology to ensure product quality and health safety

As consumers have increasingly higher requirements for food quality, hygiene and safety, manufacturers of food packaged in glass bottles such as sauces and cans are facing huge challenges. As an advanced packaging equipment, the glass bottle vacuum capping machine provides a strong guarantee for product quality, hygiene and safety with its efficient and precise performance, and injects new vitality into the sustainable development of the enterprise.

The core technology of the glass bottle vacuum capping machine lies in its vacuuming and capping functions. Vacuuming technology can effectively eliminate the air in the bottle and prevent the sauce from oxidizing and deteriorating during storage, thereby extending the shelf life of the product. The screw-cap technology ensures that the cap fits the bottle mouth tightly, effectively preventing sauce leakage and contamination. The combination of these two technologies not only improves the quality of products, but also protects the health and safety of consumers.

In the market, vacuum packaging methods are widely used for glass bottle products such as chili sauce, fermented bean curd, canned fruits, canned meat, and canned marine fish. As an important piece of equipment in the production line of these products, the glass bottle vacuum capping machine plays an irreplaceable role. It can quickly complete sauce filling, vacuuming, capping and other processes, greatly improving production efficiency. At the same time, the design of its automated production line solves the problems of low production efficiency, loose packaging, and air leakage in traditional production methods, further improving the quality of the product.

It is worth mentioning that the application of glass bottle vacuum capping machines in sauce companies also reflects its energy-saving and environmentally friendly characteristics. By optimizing the equipment structure and control system, the equipment not only reduces energy consumption, but also reduces waste emissions during the production process, meeting the requirements of green production of modern enterprises.

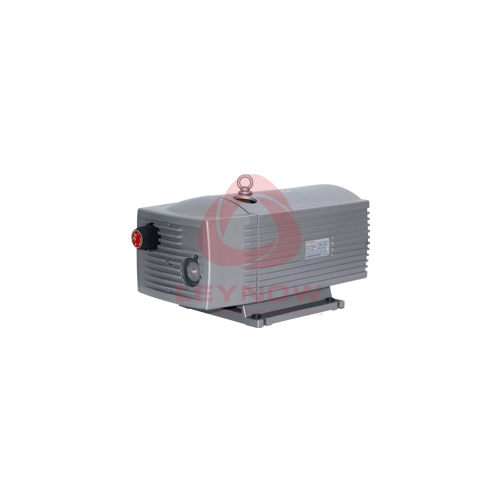

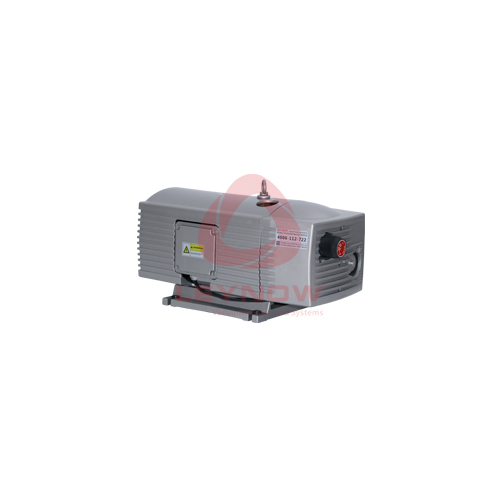

Among the core components of the glass bottle vacuum capping machine, the application of LeyNow vacuum pump is particularly important. With its efficient, stable and reliable performance, LeyNow vacuum pump provides powerful power support for vacuum capping machines. During the vacuuming process, the LeyNow vacuum pump can quickly and accurately extract the air from the bottle to create an ideal vacuum environment. At the same time, its precise vacuum control function can ensure that each bottle can meet the predetermined vacuum requirements, thereby ensuring the packaging quality of the product.

The application of LeyNow vacuum pumps not only improves the working efficiency of the glass bottle vacuum capping machine, but also reduces the energy consumption and maintenance costs of the equipment. Its efficient working performance makes the vacuuming process faster and more stable, improving overall production efficiency. At the same time, its reliable operational stability also reduces equipment failure rates and maintenance costs. In addition, LeyNow vacuum pumps are energy-saving and environmentally friendly, meeting the requirements of modern enterprises for green production.

In addition to the application of LeyNow vacuum pumps, the glass bottle vacuum capping machine also uses a number of advanced technical means, such as automated control systems, high-precision sensors, etc., to further improve the automation and intelligence level of the equipment. The application of these technologies enables the equipment to automatically adjust working parameters and process flows according to different product characteristics and packaging requirements, achieving personalized and precise packaging production.

With the continuous advancement of technology and the continuous development of the market, glass bottle vacuum capping machines will continue to develop in a more efficient, smarter and more environmentally friendly direction. The performance of core components such as LeyNow vacuum pumps will also be further improved and optimized, providing stronger support for the development of glass bottle vacuum capping machines.

In general, the glass bottle vacuum capping machine, with its advanced technology and excellent performance, provides a strong guarantee for the production of glass bottle packaged foods such as sauces. It can not only improve production efficiency and reduce production costs, but also ensure the quality and health safety of products and meet consumers' demand for high-quality food. In the future, with the continuous innovation of technology and the continuous expansion of the market, glass bottle vacuum capping machines will be applied and promoted in more fields, making greater contributions to the sustainable development of enterprises and the prosperity and progress of society.

Article source:https://www.leynow.com.cn/news/1009.html

Disclaimer: If the article needs to be reprinted, please indicate the source. Some articles and pictures on this site come from online editors. If there are any copyright issues, please communicate and resolve them in time.

LeyNow Company is a high-tech enterprise that develops, sells vacuum pumps and provides solutions in the vacuum field. It provides users with the most reliable, safe and easy-to-use vacuum equipment products and high-quality professional services to help global customers and partners achieve success. The company's main products include: rotary vane vacuum pumps, screw vacuum pumps, Roots vacuum pumps, piston vacuum pumps, etc.

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business CHN

CHN