LeyNow is committed to the development and research of new energy sources and provides professional vacuum solutions for the photovoltaic industry. Etching, PECVD and lamination – at Leno you will find high quality and high reliability vacuum systems for optimal performance.

Advantages

Photovoltaic

Various processes such as crystalline silicon, CdTe, CIGS or silicon thin film technology are used to produce photovoltaic cells that capture sunlight and convert it into energy. These are inseparable from the development of vacuum technology.

Photovoltaic cell production

From the drawing of silicon crystals to the production of solar cells to the stacking of solar modules – these manufacturing processes would not be possible without a vacuum. It doesn’t matter whether the focus is on crystallization or thin film coating – tailor-made vacuum solutions are a key factor in photovoltaic production. As solar panel production volumes increase, this area of production is becoming increasingly important. Leno provides high-quality products and excellent solutions for this market.

Laminated

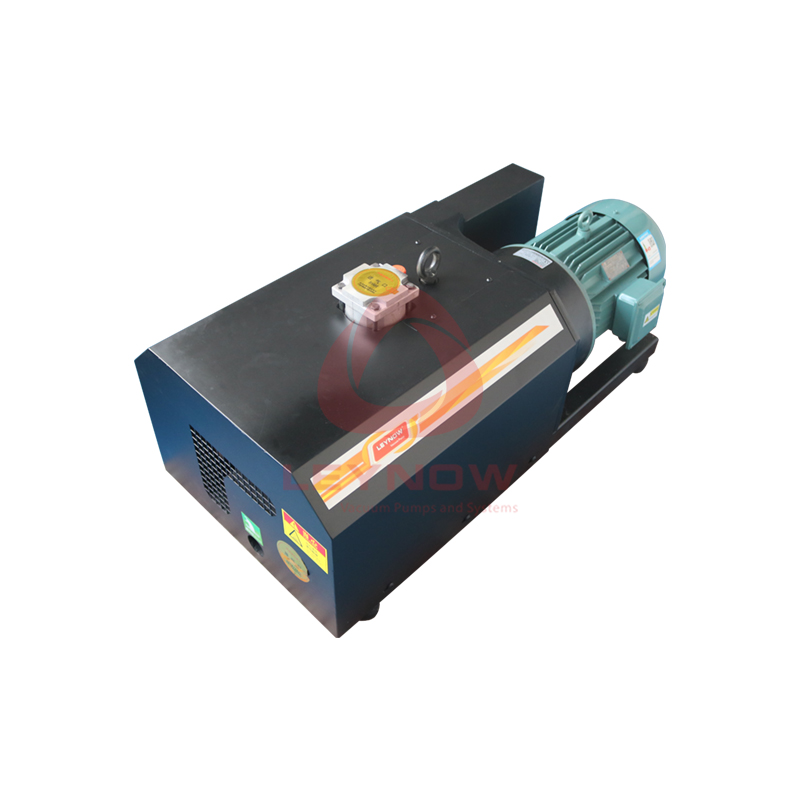

The lamination process of solar cells consists in encapsulating the solar cells while connecting the front and rear protective panels. In order to achieve the best results, Leno uses its dry compression screw vacuum pump SCREWLINE, which provides a vacuum pump speed perfectly suitable for this application. Dry screw vacuum pump performance advantages: Optimized for handling by-products generated during lamination, high uptime and low maintenance costs, high vapor resistance and particle compatibility, easy on-site cleaning, low operating costs, minimal maintenance, Extended service intervals.

Thin film

A thin film is a layer of material with a thickness ranging from nanometers to several microns. Thin film technology has improved over the past few decades, requiring reliable products to achieve the best quality. For thin film deposition processes, Leno can provide best-in-class vacuum equipment using high-performance dry pumping systems to meet the requirements of the application.

Monocrystalline silicon wafer based module

Single-stage rotary vane pump in combination with Roots blower, designed for rapid evacuation of load locks and transfer chambers, robust vacuum generator for the low vacuum range, high reliability, cost-optimized.

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business CHN

CHN