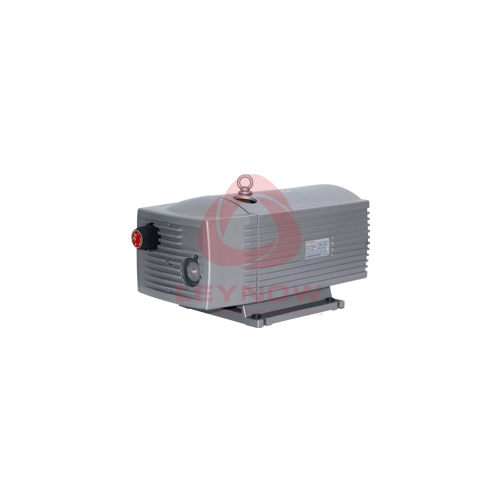

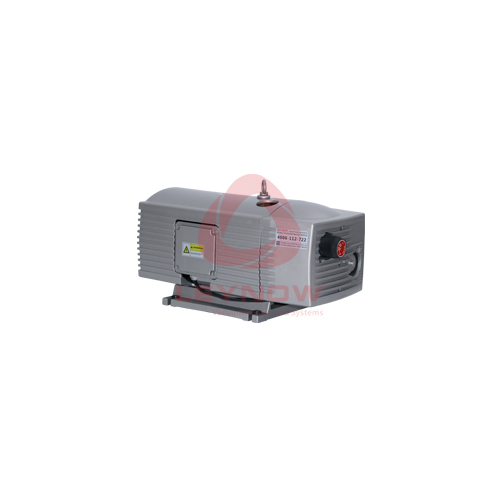

LeyNow vacuum pump : breaking through technical bottlenecks and leading the new trend in the industry

In the industrial field, vacuum pumps play an indispensable role, providing stable and reliable power support for many industries. However, with the continuous development of technology and increasing competition in the market, vacuum pumps are also facing many challenges. Against this background, LeyNow vacuum pumps have successfully broken through the limitations of traditional vacuum pumps and become the leader in the market with their excellent performance and innovative technology.

Vacuum pump, as a device for extracting gas molecules to achieve a vacuum state, is widely used in chemical industry , medicine , food and other fields. However, vacuum pumps will inevitably experience some failures during use, such as reduced suction, air leakage and other problems. These failures not only affect the working efficiency of the vacuum pump, but may also have a serious impact on the entire production process.

In response to these problems, LeyNow Vacuum Pump provides users with a full range of solutions with its advanced technology and professional team. First of all, in response to the problem of reduced suction power of the vacuum pump, LeyNow vacuum pump adopts a unique design and high-quality materials, which effectively improves the pumping efficiency. At the same time, the company also provides users with professional maintenance services to restore the normal working condition of the vacuum pump by inspecting and replacing worn parts.

In addition, LeyNow Vacuum Pump has also conducted in-depth research on the problem of vacuum pump air leakage. The company found that air leaks were often caused by aging or improperly installed seals. Therefore, during the design and production process of LeyNow vacuum pumps, special attention is paid to the selection and installation of seals. At the same time, the company also provides users with air leak detection and repair services to ensure that the vacuum pump always maintains good sealing performance during use.

In addition to solving common faults, LeyNow vacuum pumps also focus on product upgrades and innovation. The company continues to develop new technologies and materials to improve the performance and stability of vacuum pumps. At the same time, the company also continuously improves and optimizes its products based on market demand and user feedback to meet the needs of different industries and scenarios.

In terms of the selection of vacuum pump oil, LeyNow vacuum pumps also show their professionalism and rigor. Vacuum pump oil is one of the key factors for the normal operation of the vacuum pump, and its performance directly affects the service life and working efficiency of the vacuum pump. LeyNow Vacuum Pump provides users with a variety of vacuum pump oil types to choose from based on product characteristics and user needs. Among them, No. 68 vacuum pump oil and No. 100 vacuum pump oil are two common models. These two oils are different in terms of viscosity, oxidation resistance, and anti-wear properties. Users can choose according to the specific use environment and needs.

It is worth mentioning that although vacuum pump oil and engine oil are both oils used for lubrication, there are obvious differences between them. Vacuum pump oil has higher vacuum stability and lower volatility to ensure good lubrication performance in vacuum environment. Engine oil focuses more on engine lubrication and cooling, and its performance requirements are different from vacuum pump oil. Therefore, when selecting oil products, users should choose according to the specific needs of the equipment to avoid mixing or misusing them.

As a leader in the vacuum pump industry, LeyNow vacuum pumps have not only made remarkable achievements in product performance and technological innovation, but also won wide praise from users in terms of after-sales service. The company has established a complete after-sales service system to provide users with timely and professional technical support and solutions. Whether it is product installation, debugging or fault repair, LeyNow can respond quickly and provide professional services to ensure that users' production processes can proceed smoothly.

In addition, LeyNow vacuum pumps also focus on communication and cooperation with users. The company regularly communicates and collects feedback from users to understand their needs and problems during use in order to continuously improve products and services. At the same time, the company also actively participates in industry exchanges and cooperation, and works with its peers to promote the development and progress of the vacuum pump industry.

In the application of LeyNow vacuum pumps, its excellent performance and stability have been recognized by the majority of users. In the chemical industry, LeyNow vacuum pumps provide a stable and reliable vacuum environment for the production of fine chemical products; in the pharmaceutical field, its oil-free silent technology provides a quieter and more stable environment for the operation of medical equipment ; in the food field, LeyNow The vacuum pump provides powerful power support for vacuum packaging equipment, effectively extending the shelf life of food.

To sum up, with its excellent performance, innovative technology and professional services, LeyNow vacuum pumps have successfully broken through the limitations of traditional vacuum pumps and become the leader in the market. In the future, with the continuous advancement of technology and the continuous expansion of the market, LeyNow vacuum pumps will continue to adhere to the concepts of innovation, quality and service and contribute more to the development of the industry.

Article source:https://www.leynow.com.cn/news/997.html

Disclaimer: If the article needs to be reprinted, please indicate the source. Some articles and pictures on this site come from online editors. If there are any copyright issues, please communicate and resolve them in time.

LeyNow Company is a high-tech enterprise that develops, sells vacuum pumps and provides solutions in the vacuum field. It provides users with the most reliable, safe and easy-to-use vacuum equipment products and high-quality professional services to help global customers and partners achieve success. The company's main products include: rotary vane vacuum pumps, screw vacuum pumps, Roots vacuum pumps, piston vacuum pumps, etc.

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business CHN

CHN