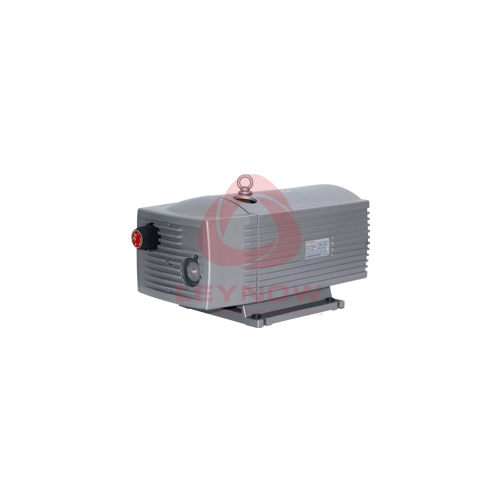

LeyNow rotary vane vacuum pump : industry leader, leading the new trend of vacuum technology

In today's industrial field, vacuum pumps play a vital role. Among many vacuum pump brands, LeyNow rotary vane vacuum pumps are gradually becoming the leader in the industry with their unique characteristics and wide range of applications.

1. Core features of LeyNow rotary vane vacuum pumps

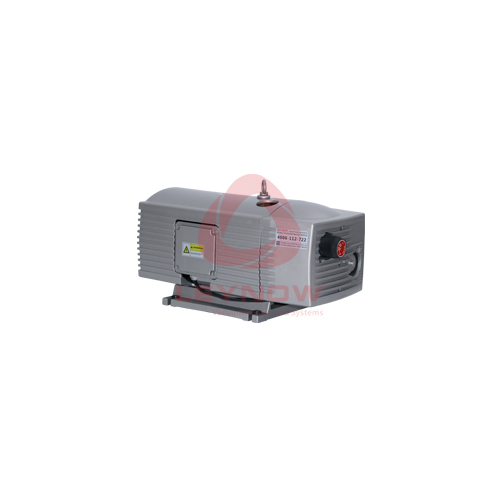

● 1. Ultra-low noise : LeyNow rotary vane vacuum pumps produce extremely low noise during operation, providing users with a quiet and comfortable working environment. This feature makes Lino rotary vane vacuum pumps have significant advantages in situations where high quietness is required, such as laboratories, hospitals, etc.

● 2. Powerful steam drainage capacity : Whether it is a high-humidity or high-pressure environment, the LeyNow rotary vane vacuum pump can maintain stable operation and effectively remove moisture and steam. This property makes it excellent in many applications where efficient steam drainage is required.

● 3. Easy maintenance : The design of the LeyNow rotary vane vacuum pump focuses on the user experience, making cleaning, maintenance, and replacement of oil seals and other components a breeze. This design not only reduces the user's maintenance costs, but also greatly increases the service life of the equipment.

● 4. Continuous operation in the full pressure range : Whether in high vacuum or low vacuum environments, LeyNow rotary vane vacuum pumps can maintain stable performance and achieve continuous operation. This feature enables it to exert excellent performance in various complex processes.

2. Wide application of LeyNow rotary vane vacuum pumps

Lino rotary vane vacuum pumps are gradually penetrating into various industrial fields with their excellent performance and diverse application fields.

● 1. Vacuum coating , sputtering, ion plating, etc .: In processes such as vacuum coating, sputtering, and ion plating, LeyNow rotary vane vacuum pumps provide a stable and efficient vacuum environment, ensuring product quality and production efficiency.

● 2. Gas replacement, filling, vacuum insulation, etc .: In applications such as gas replacement, filling, vacuum insulation, etc., Lino rotary vane vacuum pumps can quickly achieve the required vacuum degree and maintain stable operation, providing strong guarantee for the production process. .

● 3. Vacuum drying, freeze drying, etc .: In the fields of vacuum drying, freeze drying and other fields, Lino rotary vane vacuum pumps have significant advantages in handling high-humidity materials with their powerful steam drainage capabilities.

● 4. Analysis machines, leak detection devices, etc .: In applications such as analysis machines and leak detection devices, LeyNow rotary vane vacuum pumps can provide a high-precision vacuum environment to ensure the accuracy and stability of the equipment.

● 5. Vacuum packaging , vacuum adsorption, etc .: In vacuum packaging, vacuum adsorption and other industries, LeyNow rotary vane vacuum pumps have been widely praised by users for their stable and efficient performance.

3. Leading technology and excellent quality

The key reason why Lino rotary vane vacuum pumps can stand out in the fiercely competitive market lies in its leading technology and excellent quality. LeyNow has always been driven by innovation, constantly introducing and developing new technologies to provide users with more advanced and efficient vacuum pump products. At the same time, the company strictly controls product quality to ensure that every vacuum pump shipped meets high quality standards.

With the continuous advancement of science and technology and the continuous development of the market, LeyNow rotary vane vacuum pumps will continue to maintain their advantages of technological leadership and excellent quality. In the future, LeyNow will further increase investment in R&D and promote technological innovation and product upgrades. At the same time, the company will also actively expand application areas and provide better vacuum solutions for more industries.

In short, Lino rotary vane vacuum pumps are becoming the leader in the vacuum pump industry with their unique characteristics and wide range of applications. We believe that in future development, LeyNow will continue to maintain its leading position and provide more excellent products and services to users around the world.

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business CHN

CHN