Technical analysis of fully automatic chip burning machine and its working principle

1. Overview of fully automatic chip burning machine

With the rapid development of science and technology, microelectronics technology is increasingly used in various industries. As the core component of microelectronics technology, the stability and reliability of its performance are directly related to the operation effect of the entire system. As an important equipment in the chip production process, the fully automatic chip burning machine has a technical level and application effect that are directly related to the quality and production capacity of the chip.

The fully automatic chip burning machine realizes the automation and intelligence of chip burning through precise mechanical structure and electrical control system. It can not only complete the chip burning work efficiently, but also monitor and record the burning process in real time to ensure the accuracy and reliability of the burning. At the same time, the fully automatic chip burning machine is also highly flexible and adaptable, and can be quickly adjusted and optimized according to different chip types and burning needs.

2. Working principle of fully automatic chip burning machine

The working principle of the fully automatic chip burning machine is mainly based on chip burning technology and automatic control technology. During the chip burning process, the burner first identifies the chip through the identification system and determines the chip model and burning requirements. Then, the burning machine writes the burning data into the chip through the burning head according to the preset burning program. During the burning process, the burning machine performs real-time verification and error correction on the burning data to ensure the accuracy and reliability of burning.

Automation control technology is the key to achieving efficient operation of fully automatic chip burning machines. Through a precise mechanical transmission system and electrical control system, the burner can automatically complete operations such as grabbing, positioning, burning and releasing chips. At the same time, the burner also has fault self-diagnosis and automatic recovery functions, which can automatically diagnose and repair when a fault occurs to ensure the stable operation of the equipment.

3. Application and functions of fully automatic chip burning machine

Fully automatic chip burning machines play a vital role in the chip production process. It is mainly used to write preset programs or data into the chip so that the chip has specific functions or performance. Through the fully automatic chip burning machine, chips can be programmed quickly, accurately and in batches, improving the production efficiency and quality stability of the chips.

In addition, the fully automatic chip burning machine also has a variety of functions to meet different needs. For example, it can adapt to different types of chips by replacing different burning heads; optimize the burning effect by adjusting burning parameters; and perform remote monitoring and management by connecting to a host computer. The realization of these functions makes the fully automatic chip burning machine more flexible and adaptable in the chip production process.

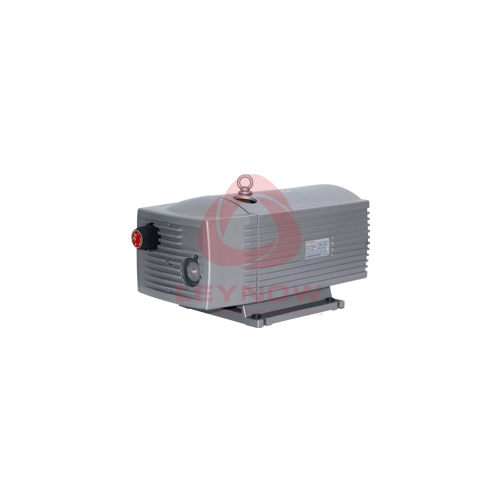

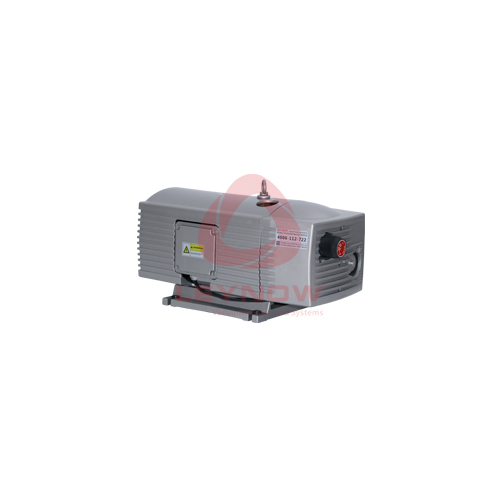

4. Application of LeyNow vacuum pump in fully automatic chip burning machine

In the operation process of the fully automatic chip burning machine, vacuum technology plays an indispensable role. As a leading supplier of vacuum equipment in the industry , LeyNow Vacuum Pump's products have been widely used in fully automatic chip burning machines.

With its efficient, stable and reliable performance characteristics, LeyNow vacuum pump provides a stable vacuum environment for fully automatic chip burning machines. During the chip burning process, the vacuum pump generates negative pressure to fix the chip on the burning station, ensuring the stability and accuracy of the chip during the burning process. At the same time, the vacuum pump can also promptly remove waste gas and tiny particles generated during the burning process, keeping the working environment clean and hygienic.

In addition, the LeyNow vacuum pump also has intelligent control functions and can be seamlessly connected with the control system of the fully automatic chip burning machine. By monitoring and adjusting the vacuum degree in real time, the vacuum pump can ensure the smooth progress of the chip burning process. At the same time, the vacuum pump also has fault self-diagnosis and remote monitoring functions to facilitate users in equipment management and maintenance.

5. Development trends and prospects of fully automatic chip burning machines

With the continuous advancement of microelectronics technology and the continuous expansion of application fields, fully automatic chip burning machines will face more challenges and opportunities. In the future, fully automatic chip burning machines will develop in a more efficient, stable, and intelligent direction.

On the one hand, with the continuous increase in chip types and the diversification of programming requirements, fully automatic chip programming machines need to have higher flexibility and adaptability. By continuously optimizing the mechanical structure and electrical control system, rapid identification and accurate programming of different types of chips are achieved.

On the other hand, with the continuous development of technologies such as the Internet of Things and big data, fully automatic chip burning machines will achieve more intelligent management and control. By connecting to the cloud platform or host computer system, functions such as remote monitoring, fault diagnosis, and data analysis can be realized to improve equipment management efficiency and operational stability.

In addition, with the continuous improvement of environmental awareness and the continuous increase of energy consumption, fully automatic chip burning machines need to pay attention to energy conservation, environmental protection and green production. By using low-power, high-efficiency electrical components and energy-saving technology, the operating costs and energy consumption of the equipment are reduced.

To sum up, the fully automatic chip burning machine is an important equipment in the chip production process, and its technical level and application effect will directly affect the quality and production capacity of the chip. With the continuous advancement of technology and the continuous expansion of application fields, fully automatic chip burning machines will usher in broader development prospects.

LeyNow vacuum pumps are widely used in many fields due to their excellent pumping performance, stability and durability. In the field of semiconductor manufacturing, LeyNow vacuum pumps are used to create high vacuum environments to ensure the accuracy and stability of chip manufacturing. In scientific research experiments, it is used to provide clean, interference-free vacuum conditions to ensure the accuracy of experimental results. At the same time, in the fields of medical, chemical , aerospace and other fields, LeyNow vacuum pumps also play an indispensable role, such as vacuum suction for medical equipment , vacuum distillation for chemical reactions, and vacuum testing of spacecraft. These rich application scenarios fully demonstrate the powerful application capabilities and broad market prospects of LeyNow vacuum pumps.

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business CHN

CHN