Analysis of negative pressure 90Kpa vacuum degree and its significance in technical applications

In the field of vacuum technology, vacuum degree is a crucial parameter. It describes the rarity of gas molecules in a certain space and is usually expressed in pressure units. Among them, negative pressure is a key concept, which represents the degree of pressure reduction relative to atmospheric pressure. This article will analyze in detail the degree of vacuum corresponding to a negative pressure of 90Kpa, and explore the relationship between positive pressure and negative pressure in the degree of vacuum, as well as the corresponding relationship between MPa and Pa in negative pressure. At the same time, we will also introduce the applications of LeyNow vacuum pumps in related fields.

First of all, we need to clarify the meaning of vacuum degree of negative pressure 90Kpa. In vacuum technology, Kpa (kilopascal) is a commonly used pressure unit used to express gas pressure. Negative pressure of 90Kpa means that the gas pressure in this space is 90Kpa lower than the atmospheric pressure. Atmospheric pressure is about 101.325Kpa. Therefore, the gas pressure in a space with a negative pressure of 90Kpa is about 11.325Kpa. Such a degree of vacuum is very important in many industrial and scientific experiments, especially where gas interference needs to be eliminated or high-precision measurements must be made.

Next, we explore the relationship between positive pressure and negative pressure in vacuum. Positive pressure refers to pressure above atmospheric pressure, while negative pressure refers to pressure below atmospheric pressure. In vacuum technology, we usually focus on negative pressure because it involves the need to exclude gases and create an environment free of gas interference. Positive pressure and negative pressure are opposites in nature, but together they make up the complete range of gas pressures. In practical applications, the conversion of positive pressure and negative pressure often requires specific equipment and technology, such as vacuum pumps and pressure regulating valves.

Among the measurement units of negative pressure, MPa (MPa) and Pa (Pascal) are two commonly used units. MPa is a larger unit, 1MPa is equal to 1000Kpa, and Pa is the basic unit, 1Kpa is equal to 1000Pa. Therefore, when describing the degree of vacuum, we need to choose the appropriate unit according to actual needs. For example, when describing a higher vacuum degree, MPa may be more appropriate; while when describing a lower vacuum degree, Pa or Kpa are more commonly used.

After understanding the meaning of the vacuum degree of negative pressure 90Kpa and the relationship between positive pressure and negative pressure, we further explore the application of this vacuum degree in actual technology. In industrial production, many processes need to be carried out under a certain degree of vacuum, such as vacuum drying, vacuum smelting, vacuum coating , etc. These processes have different requirements for vacuum degree, but they all need to be achieved by vacuum pumps and other equipment.

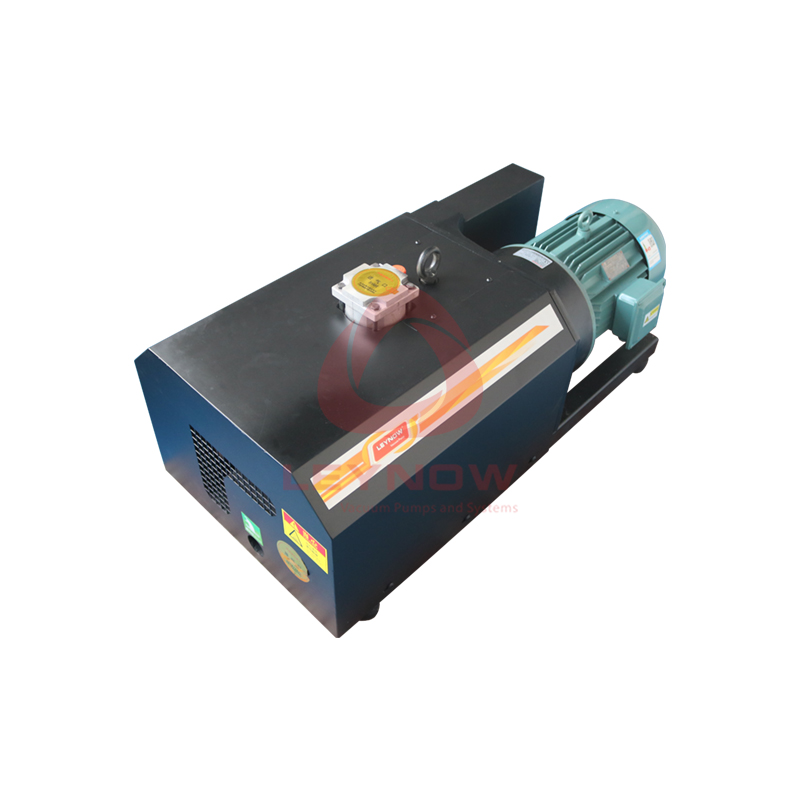

Among them, LeyNow vacuum pump, as an efficient and reliable vacuum equipment , has been widely used in many fields. Laino vacuum pump adopts advanced vacuum technology, which can achieve high vacuum degree in a short time, and is stable in operation and easy to maintain. Under the vacuum degree requirement of negative pressure 90Kpa, LeyNow vacuum pump can easily meet the demand and provide a stable and reliable vacuum environment for industrial production.

Specifically, LeyNow vacuum pumps are widely used in the following fields:

1. Electronics industry: In processes such as semiconductor manufacturing and integrated circuit packaging, it is necessary to create a high-cleanliness vacuum environment. LeyNow vacuum pumps can efficiently remove gas and ensure the stability of the production process and product quality.

2. Scientific research experiments: In experiments in physics, chemistry , materials science and other fields, it is often necessary to conduct them under a specific vacuum degree. LeyNow vacuum pumps can provide a stable and controllable vacuum environment for these experiments and promote the progress of scientific research work.

3. Food processing: In the processes of food drying and preservation, vacuum technology can improve product quality and extend shelf life. LeyNow vacuum pumps are widely used in the food processing industry due to their high efficiency and energy saving characteristics.

4. Pharmaceutical production: In the pharmaceutical process, some drugs need to be prepared under a specific vacuum degree. LeyNow vacuum pumps can meet these special needs and provide strong technical support for pharmaceutical production.

In summary, negative pressure 90Kpa, as an important vacuum degree indicator, has wide application value in industrial production, scientific research experiments and other fields. As an efficient and reliable vacuum equipment, LeyNow vacuum pump plays an important role in these fields. With the continuous development of science and technology, vacuum technology will be applied in more fields and make greater contributions to the progress and development of human society.

In practical applications, we also need to pay attention to the measurement and monitoring of vacuum degree. Accurate vacuum measurement is key to ensuring process stability and reliable quality. Therefore, we need to choose a suitable vacuum gauge to monitor changes in vacuum degree in real time, and adjust and control it as needed. At the same time, we also need to regularly maintain and maintain the vacuum pump to ensure its long-term stable operation and efficient performance.

In short, the vacuum degree of negative pressure 90Kpa is of great significance in technical applications. By having an in-depth understanding of the concept, units and measurement methods of vacuum degree, and selecting appropriate vacuum equipment and technology based on actual application needs, we can better utilize vacuum technology to provide strong support for industrial production, scientific research experiments and other fields. As one of the leaders, LeyNow vacuum pumps are widely used in many fields with their efficient and reliable performance, making important contributions to the development and application of vacuum technology.

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business CHN

CHN