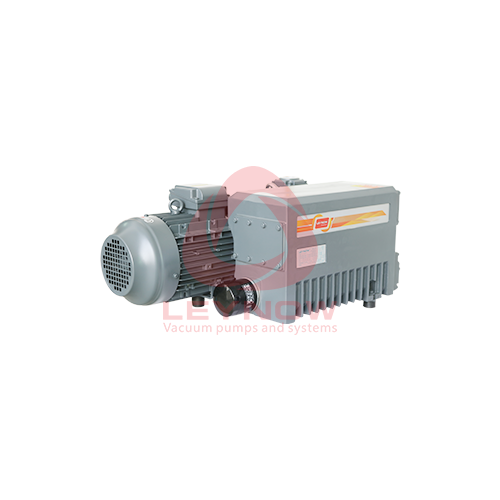

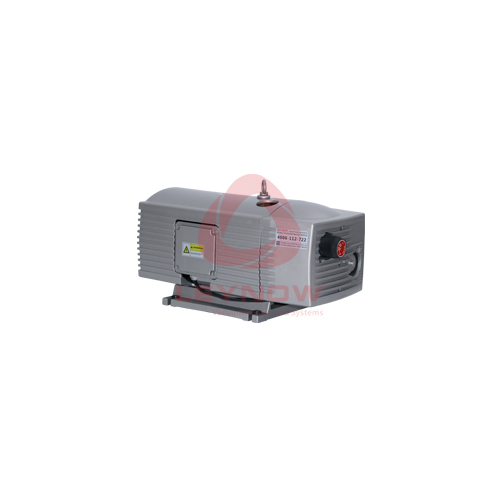

■The single-stage oil rotary vane vacuum pump is an oil-sealed mechanical vacuum pump. Its working pressure range is usually 101325~1.33×10^-2 (Pa), which belongs to the category of low vacuum pumps.

■The pump has the characteristics of low cost, low noise, easy maintenance, strong applicability and energy saving, and is widely used in many fields.

The following are the main application areas of Leynow single-stage oil rotary vane vacuum pumps:

Industrial production:

■Metallurgy: In the metallurgical industry, single-stage oil rotary vane vacuum pumps can be used in various smelting and vacuum processing processes.

■Machinery: In the field of machinery manufacturing, this pump can be used in processes such as vacuum holding and vacuum clamping.

■Electronics: In the electronics industry, single-stage oil rotary vane vacuum pumps can be used in semiconductor manufacturing, vacuum coating and other processes.

■Chemical industry: In the field of fine chemicals, this pump can be used in vacuum filtration, vacuum evaporation, vacuum distillation, vacuum impregnation, vacuum drying and other processes.

■Light industry: In light industry, such as food packaging, tobacco processing and other industries, this pump can be used for vacuum packaging, vacuum suction and other processes.

■Petroleum: Single-stage oil rotary vane vacuum pumps also have important applications in oil extraction, transportation and oil field water injection systems, as well as in the process of leaching negative pressure evaporation and oil and gas recovery.

Scientific research fields:

■In the scientific research department, single-stage oil rotary vane vacuum pumps are often used in various vacuum experiments and tests to provide the required vacuum environment.

Other applications:

■Solar energy industry: In the solar energy industry, the pump can be used in automated process chains such as monocrystalline silicon and polycrystalline silicon production furnaces, solar panel cutting, and solar vacuum lamination.

■Food industry: In the food industry, single-stage oil rotary vane vacuum pumps can be used for vacuum packaging and drying of sausages, ham and other products, as well as humidification of tobacco, vacuum dehydration of dried fruits and vegetables, and sterilization of special foods.

■It should be noted that although single-stage oil rotary vane vacuum pumps are widely used, they also have their limitations. For example, it cannot extract gases that contain too much oxygen, are corrosive to metals, have chemical reactions with pump oil, and contain particulate dust. In addition, this pump cannot be used as a transfer pump or compression pump.

■Single-stage oil rotary vane vacuum pumps play an important role in industrial production, scientific research and many other industries with their unique performance and wide range of applications.

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

Official Account

Official Account WeChat Business

WeChat Business

CHN

CHN